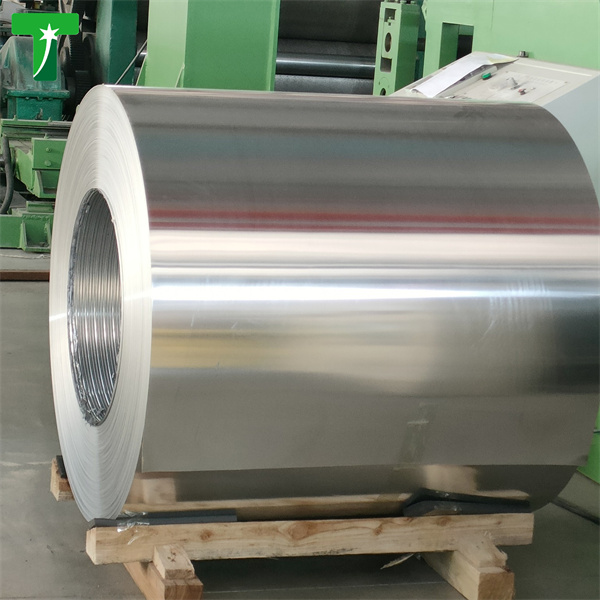

DC51D Galvanized Carbon Steel Coil for Construction

Product Introduction

DC51D is a galvanized carbon steel coil conforming to the European Standard EN 10346. It is a structural-grade steel with excellent formability and corrosion resistance due to its zinc coating. It is widely used in construction, automotive components, home appliances, and general manufacturing.

Advantages

|

Advantage |

Description |

|

Excellent formability |

Suitable for various cold - forming processes such as stamping, bending, and drawing, facilitating the production of complex - shaped components. |

|

Good corrosion resistance |

The zinc coating on the surface isolates the base metal from the external environment, effectively preventing rust and corrosion, and prolonging the service life. |

|

Favorable surface quality |

Has a smooth and clean surface, which is beneficial for subsequent painting, coating, and printing processes, and ensures good adhesion of the coating. |

|

Good weldability |

Easy to weld with other components, enabling the production of reliable and strong structures. |

|

Cost - effectiveness |

Offers a good balance between performance and cost, with relatively low cost and excellent properties, reducing overall costs. |

|

Wide range of applications |

Widely used in the automotive, construction, and home appliance industries, etc. |

Packaging

FAQ

Q:What is DC51D Galvanized Carbon Steel Coil?

A:A commonly used galvanized steel coil suitable for general forming processing, with a zinc coating on the surface to prevent rust.

Q:How to choose specifications when purchasing?

A:Choose thickness (such as 0.5 - 1.2mm is commonly used), width (common 1000 - 1500mm) and roll weight according to the usage scenario.

Q:Where is it mainly used?

A:It is commonly used in building roofs, walls, home appliance casings (such as refrigerators, washing machines), and auto parts.

|

TYPSA |

||

|

Aspect |

LAMINA FRIA |

|

|

Minimum |

Maximum |

|

|

Weight (Kg) |

8,000 |

12,000 |

|

Width (mm) |

1000 |

1219 |

|

External diameter (mm) |

There is no specification |

Do not exceed the specified weight |

|

Internal diameter (mm) |

507 |

780 |

|

Ovality (mm) |

There is no specification |

There is no specification |

TUBAC permitted weights, diameters, widths and ovality(information for supplier use)

|

Aspect |

SLITTER # 4 |

|

|

Minimum |

Maximum |

|

|

Thickness |

0.6 |

2 |

|

Weight (Kg) |

6,000 |

16,000 |

|

Width (mm) |

904 |

1300 |

|

External diameter (mm) |

There is no specification |

1,800 |

|

Internal diameter (mm) |

484 |

762 |

|

Ovality (mm) |

25 |

25 |

TUBAC permitted weights, diameters, widths and ovality(information for internal use)

|

Aspect |

BONAK |

|

|

Minimum |

Maximum |

|

|

Thickness |

8 |

0.7 |

|

Weight (Kg) |

22,000 |

11,000 |

|

Width (mm) |

1800 |

500 |

|

External diameter (mm) |

2200 |

1500 |

|

Internal diameter (mm) |

860 |

508 |

|

Ovality (mm) |

25 |

25 |

Chemical composition of cold rolled sheet

|

Element (%) |

JIS G3141 SPCCT - SD |

ASTM A1008 CS-B |

|

C (max) |

0.15 |

0.02 - 0.15 |

|

Mn (max) |

1.00 |

0.60 |

|

P (max) |

0.100 |

0.025 |

|

S (max) |

0.035 |

0.035 |

Reference standard: JIS G3141, SPCCT-SD grade

Reference standard: ASTM A1008 CS-B

JIS G3141: Japanese Standard

SPCC: Indicates the grade for a commercial quality steel (Table No. 1 JIS G3141 Standard)

T: Consensus voltage resistance level (Table No. 5, note C, JIS G3141 Standard)

S: Standard hardness level (Table No. 2 JIS G3141 Standard)

D: Matte surface finish (Table No. 3 JIS G3141 Standard)

NOTE: Boron must be less than 0.0008% according to the Central American SAC Tariff system.

NOTE: If you wish to purchase cold rolled sheet with a different specification than the one in Table No. 1, you must do so using the FRM-0AI00003-15 Request for Exception to a Standard format, according to the standard EO-0AI00003-07 Non-compliance with standard.

5.2.Mechanical Specifications

Measurement method: Tensile test carried out on a universal mechanical testing machine according to ASTM A370 standard.

Mechanical properties of cold rolled sheet

|

Element (%) |

JIS G3141 SPCCT - SD |

ASTM A1008 CS-B |

|

Tensile strength (Mpa) min |

290 |

- |

|

Yield strength (Mpa) |

205 - 275 |

160 - 260 |

|

Elongation (%) min |

30 |

30 |

Reference standard: JIS G3141, SPCCT-SD grade

Reference standard: ASTM A1008 CS-B

JIS G3141: Japanese Standard

o SPCC: Indicates the grade for a commercial quality steel (Table No. 1 JIS G3141 Standard)

o T: Consensus voltage resistance level (Table No. 5, note C, JIS G3141 Standard)

Your email address will not be published. Required fields are marked with *

Their products are of excellent quality and they offer generous discounts. This is their third cooperation