Carbon Seamless Steel Pipe: Unrivaled Advantages and Versatile Application Scenarios

2025-09-09 11:12:14

Carbon Seamless Steel Pipe: Unrivaled Advantages and Versatile Application Scenarios

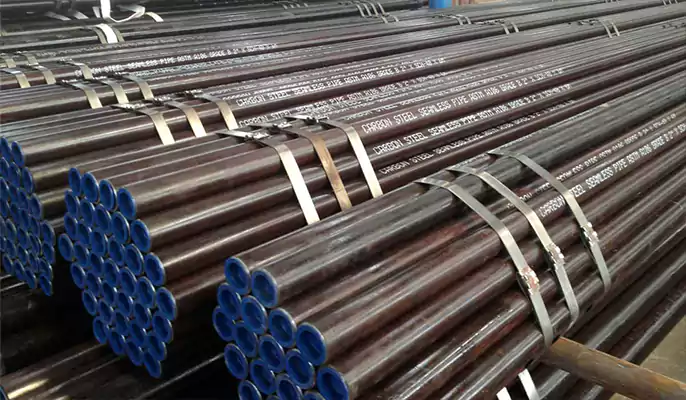

In the global industrial landscape, Carbon Seamless Steel Pipes stand out as a cornerstone of infrastructure and manufacturing. Unlike welded steel pipes, these pipes are manufactured without joints, leveraging the inherent strength of carbon steel to deliver exceptional reliability in high-pressure, high-stress environments. From energy transmission to construction, their unique combination of performance, cost-effectiveness, and adaptability makes them indispensable across diverse sectors. Below is a detailed exploration of their core advantages and typical application scenarios.

Core Advantages of Carbon Seamless Steel Pipes

Carbon Seamless Steel Pipes outperform alternative piping solutions in key metrics that matter most to industries—strength, pressure resistance, durability, and cost-efficiency. These advantages stem from their seamless manufacturing process and the inherent properties of carbon steel.

1. Exceptional Structural Strength & Pressure Resistance

The absence of welded joints is the defining strength of carbon seamless steel pipes. Welds are often the weak point in traditional pipes, prone to cracking or leaking under high pressure or thermal stress. In contrast:

- Uniform stress distribution: Seamless pipes have a continuous, homogeneous structure that distributes pressure evenly across the pipe wall. This allows them to withstand significantly higher working pressures—ranging from 10 MPa to 100 MPa (depending on grade and wall thickness)—making them ideal for high-pressure systems like steam boilers or oil pipelines.

- High tensile strength: Premium grades (e.g., ASTM A106 Grade B) boast a minimum tensile strength of 485 MPa and yield strength of 275 MPa, enabling them to resist deformation even under extreme mechanical loads (e.g., heavy machinery vibrations in construction).

For example, in a thermal power plant, carbon seamless steel pipes transport superheated steam at 540°C and 16 MPa—conditions where welded pipes would risk joint failure.

2. Superior Durability & Corrosion Resistance (With Proper Treatment)

Carbon steel’s natural toughness, combined with the seamless design, translates to long service life and reduced maintenance:

- Resistance to wear and impact: The dense, grain-structure of seamless carbon steel makes it highly resistant to abrasion (e.g., from sediment in water pipelines) and mechanical impact (e.g., during construction or transportation). Uncoated carbon seamless pipes typically last 15–20 years in dry indoor environments; with anti-corrosion treatments (e.g., epoxy coating, galvanization), this lifespan extends to 30+ years.

-

Controlled corrosion risk: While plain carbon steel is susceptible to rust in moist or acidic environments, targeted treatments address this:

- Galvanization (zinc coating) protects against outdoor exposure (e.g., outdoor water mains).

- Fusion-bonded epoxy (FBE) coating resists soil corrosion for buried oil/gas pipelines.

- For mild acidic conditions (e.g., industrial cooling water), adding a thin plastic liner further enhances corrosion resistance.

3. Excellent Dimensional Precision & Versatility

Carbon seamless steel pipes are manufactured to strict dimensional tolerances, ensuring compatibility with fittings and systems worldwide:

- Consistent dimensions: Standards like ASTM A53 and GB/T 8163 mandate tight control over outer diameter (OD), inner diameter (ID), and wall thickness. For example, a 108mm OD pipe has an OD deviation of ≤±0.75%, ensuring a perfect fit with flanges, valves, or threaded connections.

- Wide range of sizes: Available in diameters from 6mm (micro-pipes for precision machinery) to 630mm (large-diameter pipes for water treatment plants) and wall thicknesses from 1mm to 60mm. This versatility means they can be tailored to almost any flow rate or pressure requirement.

- Adaptable to processing: Seamless pipes are easy to cut, bend, thread, or weld (if needed for custom installations), making them suitable for complex system designs (e.g., curved pipelines in shipbuilding).

4. Cost-Effectiveness & Accessibility

Compared to alloy steel or non-metallic pipes (e.g., stainless steel, fiberglass), carbon seamless steel pipes offer unmatched value:

- Lower material costs: Carbon steel is abundant and affordable, with seamless pipes priced 30–50% lower than stainless steel seamless pipes of the same size.

- Reduced installation and maintenance costs: Their durability minimizes replacement frequency, while their compatibility with standard fittings eliminates the need for expensive custom components. For example, a municipal water project using carbon seamless pipes can cut lifecycle costs by 25% compared to using PVC pipes (which require more frequent repairs).

- Global availability: Carbon seamless steel pipes are produced by manufacturers worldwide, ensuring stable supply and short lead times—critical for time-sensitive projects (e.g., emergency infrastructure repairs).

Typical Application Scenarios of Carbon Seamless Steel Pipes

Carbon Seamless Steel Pipes are deployed across industries where strength, pressure resistance, and cost-efficiency are non-negotiable. Their adaptability to different environments and treatments makes them a go-to choice for both standard and specialized needs.

1. Oil & Gas Industry

The oil and gas sector relies heavily on carbon seamless steel pipes for upstream extraction, midstream transmission, and downstream refining:

- Upstream (drilling and production): Pipes grade API 5L (e.g., Grade B, X42) transport crude oil and natural gas from wellheads to processing facilities. Their high pressure resistance (up to 80 MPa) withstands the intense pressure of downhole fluids, while FBE coating protects against corrosion in harsh offshore or desert environments.

- Midstream (transmission pipelines): Large-diameter (219mm–630mm) carbon seamless pipes form cross-country gas pipelines, capable of moving gas at 8–10 MPa over thousands of kilometers. For example, the TransCanada Pipeline uses carbon seamless steel pipes to transport natural gas from Alberta to Ontario.

- Downstream (refineries): Pipes like ASTM A106 Grade B handle high-temperature hydrocarbons (up to 480°C) in distillation columns and catalytic crackers, where their heat resistance and strength prevent leaks.

2. Power Generation

Power plants (thermal, nuclear, and hydropower) depend on carbon seamless steel pipes for fluid and steam transport:

- Thermal power plants: Pipes carry superheated steam (540°C, 16 MPa) from boilers to turbines and cool water from condensers. The seamless design ensures no steam leaks, which could lead to efficiency losses or safety hazards.

- Nuclear power plants: Low-carbon seamless steel pipes (e.g., ASTM A333 Grade 6) transport cooling water in secondary loops, as their low carbon content reduces the risk of radiation-induced embrittlement.

3. Construction & Infrastructure

Carbon seamless steel pipes are foundational to building and civil engineering projects:

- Water supply and sewage systems: Galvanized carbon seamless pipes are used for underground water mains, as their corrosion resistance prevents rust from contaminating drinking water. In sewage systems, epoxy-coated pipes resist chemical corrosion from wastewater.

- Structural applications: Small-diameter seamless pipes (20mm–50mm) serve as support columns, handrails, or scaffolding in high-rise buildings. Their high strength-to-weight ratio ensures structural stability without adding excess weight.

- Heating, Ventilation, and Air Conditioning (HVAC): Seamless pipes transport hot/cold water in HVAC systems, as their smooth inner surface reduces friction and improves flow efficiency—lowering energy consumption for pumps.

4. Machinery & Manufacturing

Manufacturing industries use carbon seamless steel pipes for equipment components and fluid transport:

- Automotive and aerospace: Thin-walled seamless pipes (1mm–3mm) are used in car exhaust systems and aircraft hydraulic lines. Their precision dimensions ensure a tight fit with engine components, while their strength resists vibration and heat.

- Heavy machinery: Pipes form hydraulic cylinders in excavators, cranes, and forklifts. They withstand the high pressure of hydraulic fluid (up to 30 MPa), ensuring reliable operation of lifting and digging mechanisms.

- Food and beverage processing: Sanitized carbon seamless pipes (with food-grade epoxy liners) transport liquids like milk, juice, or beer. Their smooth inner surface prevents bacterial buildup, complying with food safety standards (e.g., FDA regulations).

5. Shipbuilding & Marine Engineering

Marine environments demand pipes that resist saltwater corrosion and mechanical stress—requirements met by carbon seamless steel pipes:

- Ship hulls and systems: Pipes transport fuel, cooling water, and ballast water on ships. Galvanized or marine-grade epoxy-coated seamless pipes resist saltwater corrosion, while their strength withstands the dynamic forces of waves and ship movement.

- Offshore platforms: Seamless pipes connect offshore oil rigs to subsea wellheads, enduring high pressure (up to 100 MPa) and extreme weather conditions (e.g., hurricanes). Their seamless design eliminates leak points that could cause environmental disasters.

SkySteelGroup Carbon Seamless Steel Pipes bridge the gap between performance and practicality—offering the strength to handle extreme conditions, the precision to fit diverse systems, and the affordability to scale projects. Whether powering a city’s water supply, fueling a refinery, or supporting a skyscraper, they remain a trusted solution for industries that demand reliability without compromise. For specialized needs (e.g., high-corrosion environments), manufacturers can further enhance their properties with coatings or alloy blends—extending their utility even further.

Related Posts

Comments (2)

Katherine A. Fogg

November 25, 2024Leave a Reply

Your email address will not be published. Required fields are marked with *

Their products are of excellent quality and they offer generous discounts. This is their third cooperation