A36 Steel Plate: The Unsung Hero of Global Structural Engineering

2025-09-02 16:21:57

A36 Steel Plate: The Unsung Hero of Global Structural Engineering

Walk into any major construction site—from skyscrapers in New York to bridges in Dubai—and you’ll likely find one material working behind the scenes: A36 steel plate. As a staple of the ASTM (American Society for Testing and Materials) carbon structural steel family, A36 has earned its reputation as the "workhorse of construction" thanks to its unbeatable blend of strength, weldability, and affordability. But what makes it so universally trusted? Let’s dive into the details that make A36 a top choice for engineers worldwide.

What Exactly Is A36 Steel Plate?

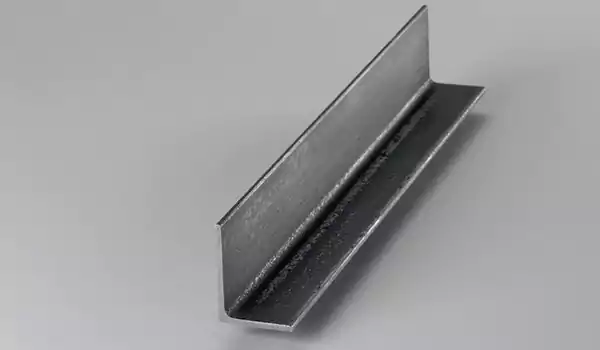

First, let’s get technical (but keep it simple). A36 is defined by the ASTM A36/A36M standard (latest 2019 edition) as a low-carbon structural steel designed for riveted, bolted, or welded applications. Think: building frames, bridges, machinery bases, and even storage tanks. It’s available in plates, bars, and profiles—making it versatile enough for both small-scale fabrications and mega-projects.

A quick note on a common mix-up: You might see "SA36" alongside A36. They’re chemically identical—the only difference is SA36 adheres to ASME (American Society of Mechanical Engineers) standards, making it ideal for pressure vessels and boiler components. No need to overcomplicate it: same great steel, just certified for different use cases.

The Numbers That Matter: A36’s Mechanical & Chemical Superpowers

What sets A36 apart isn’t just its popularity—it’s the science behind its performance. Let’s break down the key specs that make it reliable:

1. Mechanical Properties (The "Can It Handle the Job?" Test)

A36’s strength lies in its balance—strong enough to support heavy loads, but flexible enough to avoid brittle failure. Here’s what you need to know:

- Yield Strength: ≥250 MPa (36,000 psi) – This is the point where the steel stops bouncing back and starts deforming permanently. A36’s yield strength is consistent enough for most structural needs, even in thick plates.

- Tensile Strength: 400–550 MPa (58,000–79,800 psi) – The maximum stress it can take before breaking. The wide range means manufacturers can tweak it for specific projects.

- Elongation: ≥20% (2-inch gauge) – This measures flexibility. A36 stretches well before breaking, making it easy to bend, stamp, or roll into complex shapes (hello, custom steel brackets!).

- Impact Toughness: ≥27 J at 21°C (70°F) – It holds up in mild cold, though for extreme low temperatures (think: Canadian winters), look for A36 with extra impact testing.

2. Chemical Composition (The "What’s in It?" Breakdown)

A36’s low-carbon formula is the secret to its weldability. Here’s the core mix (varies slightly by thickness):

- Carbon (C): ≤0.29% – Low enough to avoid weld cracks, high enough for strength.

- Manganese (Mn): 0.80–1.35% – Boosts strength without sacrificing ductility.

- Phosphorus (P) & Sulfur (S): ≤0.04% and ≤0.05%, respectively – Strict limits to prevent brittleness (no one wants a steel that snaps unexpectedly!).

- Optional Copper (Cu): ≥0.20% – Adds a small boost to corrosion resistance, perfect for outdoor projects like bridges or utility poles.

Why Engineers Swear By A36: Real-World Applications

A36 isn’t just a lab favorite—it’s proven in some of the world’s most iconic projects:

- Golden Gate Bridge (San Francisco): Over 26,000 tons of A36 were used in its construction. Its corrosion resistance (with proper coating) has helped the bridge stand strong against 85+ years of saltwater and wind.

- Burj Khalifa (Dubai): The world’s tallest building relies on A36 for its core structural frames. Its high strength-to-weight ratio kept the design efficient—no unnecessary bulk.

- Hong Kong-Zhuhai-Macao Bridge: A36 was imported for cross-border compatibility, proving it’s a go-to for international projects where consistency matters.

But it’s not just mega-projects. A36 is everywhere:

- Industrial machinery (think: excavator frames, factory conveyors)

- Agricultural equipment (tractor bodies, grain silos)

- Commercial buildings (retail store steel beams, warehouse roofs)

A36 vs. Other Steels: When to Choose It (and When Not To)

A36 isn’t the only steel in town—so how do you know if it’s right for your project? Let’s compare it to common alternatives:

|

Steel Grade

|

Key Difference

|

Best For

|

|

A36

|

Balanced strength, weldability, and cost

|

Most structural projects (buildings, bridges, machinery)

|

|

Q235B (China)

|

Slightly lower yield strength (235 MPa)

|

Budget-friendly domestic projects (not for heavy loads)

|

|

S275 (Europe)

|

Higher yield strength (275 MPa)

|

Projects needing extra strength (heavy-duty cranes, offshore platforms)

|

|

A572 Gr. 50

|

Higher strength (345 MPa yield)

|

High-load structures (highway overpasses, skyscraper columns)

|

Pro Tip: Choose A36 if your project needs a "do-it-all" steel that’s easy to work with and won’t break the bank. If you’re dealing with extreme loads (like a 100-ton crane) or extreme environments (like a chemical plant), upgrade to a higher-strength steel like A572.

How to Get the Most Out of A36: Tips for Fabrication & Maintenance

To maximize A36’s lifespan, follow these best practices:

- Welding: Use low-hydrogen electrodes (like E7018) to avoid cracks. Preheat plates thicker than 19mm (0.75 inches) if working in cold weather.

- Coating: For outdoor use, add a layer of epoxy paint or hot-dip galvanizing. This keeps rust at bay—critical for bridges or outdoor machinery.

- Avoid Extreme Heat: A36 loses strength above 650°C (1,200°F), so don’t use it for high-temperature applications like furnace parts (opt for heat-resistant steel instead).

Final Thoughts: Why A36 Will Stay Relevant

In a world of high-tech, ultra-strong steels, A36 remains a staple because it solves a simple problem: it’s reliable, affordable, and easy to work with. Whether you’re building a small workshop or a landmark bridge, A36 delivers the performance you need without the premium price tag.

So next time you drive over a bridge or walk into a steel-framed building, take a moment to appreciate A36—the unsung hero holding it all together.

Got a project in mind?Please contact us.—we’d love to help you decide if A36 is the right fit!

Comments (2)

Leave a Reply

Your email address will not be published. Required fields are marked with *

Their products are of excellent quality and they offer generous discounts. This is their third cooperation