SAE1078M Hot Rolled High Carbon Steel Plate

Product Introduction

SAE1078M High Carbon Steel Plate is renowned for its superior strength and hardness, derived from a relatively high carbon content. This steel plate exhibits excellent wear - resistance, making it an ideal choice for applications that demand durability under friction, such as tool manufacturing, spring production, and the fabrication of wear - resistant components. Its mechanical properties enable it to withstand significant stress, while its relatively low ductility and toughness should be considered in design and usage.

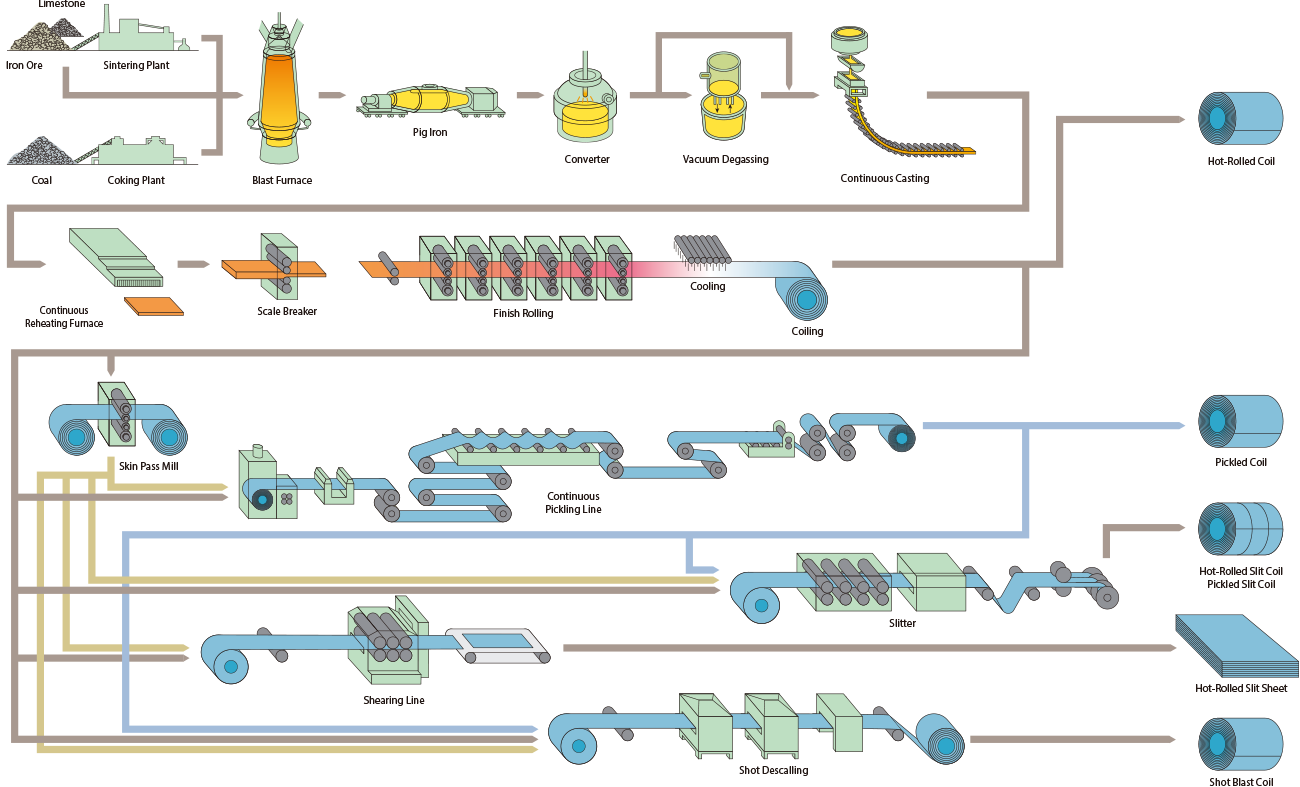

Production Process

Applications

|

Industry/Sector |

Specific Applications |

|

Automotive |

- Suspension springs, valve springs |

|

Industrial Machinery |

- Saw blades, shear tools |

|

Manufacturing & Tooling |

- Stamping dies, punches |

|

Construction & Mining |

- Excavator wear liners |

|

Consumer & Tools |

- Hammers, chisels, axes |

Packaging

FAQ

Q: What is SAE 1078M?

A: A high carbon steel (0.72–0.86% C) used for applications requiring hardness and wear resistance, such as springs, tools, and dies.

Q: Can it be heat treated?

A: Yes. Quenching + tempering achieves 50–60 HRC for improved strength and wear resistance.

Q: What are the available sizes and tolerances for SAE1078M plates?

A: Typical ranges:

Thickness: 1–100 mm (±0.1–0.5 mm tolerance).

Width: 1000–2500 mm.

Measurement method: direct measurement with digital thickness gauge and at a distance of no less than 1 inch from the edge

|

Width |

Thickness, inches |

|||||

|

0.027 a 0.051 inclusive |

0.051 a 0.057 inclusive |

0.057 a 0.071 inclusive |

0071 a 0.098 inclusive |

0.098 a 0.18 exclusive |

0.18 a 0.23 exclusive |

|

|

20 - 40 inches inclusive |

0.008 |

0.008 |

0.009 |

0.010 |

0.010 |

0.012 |

|

40 - 48 inches inclusive |

0.008 |

0.009 |

0.009 |

0.010 |

0.012 |

0.014 |

|

Width, mm |

Thickness, mm |

|||

|

Hasta 2 mm |

De 2 mm - 2.5 mm inclusive |

2.5 mm a 4.5 mm exclusive |

4.5 mm a 6.0 mm exclusive |

|

|

1200 a 1500 mm inclusive |

0.26 |

0.26 |

0.30 |

0.38 |

|

Minimum thickness, mm |

Nominal thickness, mm |

Maximum thickness, mm |

|

1.47 |

1.59 |

1.70 |

|

1.47 |

1.59 |

1.70 |

|

1.47 |

1.59 |

1.70 |

|

1.47 |

1.59 |

1.70 |

|

1.47 |

1.59 |

1.70 |

|

1.89 |

2.00 |

2.11 |

|

2.25 |

2.38 |

2.51 |

|

2.25 |

2.38 |

2.51 |

|

2.25 |

2.38 |

2.51 |

|

3.02 |

3.18 |

3.33 |

|

3.02 |

3.18 |

3.33 |

|

4.58 |

4.76 |

4.94 |

|

4.64 |

4.76 |

4.89 |

|

4.61 |

4.76 |

4.91 |

|

4.58 |

4.76 |

4.94 |

|

4.56 |

4.76 |

4.97 |

|

4.56 |

4.76 |

4.97 |

|

1.87 |

2.00 |

2.13 |

|

2.85 |

3.00 |

3.15 |

The width tolerance must be according to what is established in table 6 and 7 of the ASTM A568 standard (English System) depending on whether it is a mill edge or cut edge. There is no negative tolerance, only positive.

Width tolerance for mill Edge hot rolled Steel sheet

|

Width, inches |

Upper tolerance, no tolerance under specified width |

|

30 a 50 included |

+1 1/8” |

Width tolerance for cut Edge for hot rolled Steel sheet

|

Width, inches |

Upper tolerance, no tolerance under specified width |

|

30 to 48 inches (included) |

+3/16” |

Measurement method: direct measurement using a measuring tape

|

Hot rolled steel sheet |

Minimum width, mm |

Nominal width, mm |

Maximum width, mm |

|

3' X 6' X 1/16" |

914.40 |

914.40 |

919.16 |

|

3' X 6' X 3/16" |

914.40 |

914.40 |

919.16 |

|

3' X 7' X 1/16" |

914.40 |

914.40 |

919.16 |

|

3' X 8' X 1/16" |

914.40 |

914.40 |

919.16 |

|

3' X 8' X 3/16" |

914.40 |

914.40 |

919.16 |

|

4' X 8' X 1/16" |

1219.20 |

1219.20 |

1223.96 |

|

4' X 8' X 1/8" |

1219.20 |

1219.20 |

1223.96 |

|

4' X 8' X 3/16" |

1219.20 |

1219.20 |

1223.96 |

|

4' X 8' X 2.0mm |

1219.20 |

1219.20 |

1223.96 |

|

4' X 8' X 3.0mm |

1219.20 |

1219.20 |

1223.96 |

|

4' X 8' X 3/32" |

1219.20 |

1219.20 |

1223.96 |

|

4' X 10' X 1/16" |

1219.20 |

1219.20 |

1223.96 |

|

4' X 10' X 1/8" |

1219.20 |

1219.20 |

1223.96 |

|

4' X 10' X 3/16" |

1219.20 |

1219.20 |

1223.96 |

The length tolerance must be in accordance with what is established in table 8 of the ASTM A568 standard. There is no negative tolerance, only positive.

|

Length, inches |

Tolerance over, no tolerance under |

|

60 a 120 (included) (6, 7, 8, 9 y 10 pies) |

+ ¾” |

Measurement method: direct measurement using a measuring tape

|

Hot rolled steel sheet |

Minimum length, mm |

Nominal length, mm |

Maximum length, mm |

|

3' X 6' X 1/16" |

1828.80 |

1828.80 |

1847.85 |

|

3' X 6' X 3/16" |

1828.80 |

1828.80 |

1847.85 |

|

3' X 7' X 1/16" |

2133.60 |

2133.60 |

2152.65 |

|

3' X 8' X 1/16" |

2438.40 |

2438.40 |

2457.45 |

|

3' X 8' X 3/16" |

2438.40 |

2438.40 |

2457.45 |

|

4' X 8' X 1/16" |

2438.40 |

2438.40 |

2457.45 |

|

4' X 8' X 1/8" |

2438.40 |

2438.40 |

2457.45 |

|

4' X 8' X 3/16" |

2438.40 |

2438.40 |

2457.45 |

|

4' X 8' X 2.0mm |

2438.40 |

2438.40 |

2457.45 |

|

4' X 8' X 3.0mm |

2438.40 |

2438.40 |

2457.45 |

|

4' X 8' X 3/32" |

2438.40 |

2438.40 |

2457.45 |

|

4' X 10' X 1/16" |

3048.00 |

3048.00 |

3067.05 |

|

4' X 10' X 1/8" |

3048.00 |

3048.00 |

3067.05 |

|

4' X 10' X 3/16" |

3048.00 |

3048.00 |

3067.05 |

Maximum straightness should be according to table 10 of ASTM A568 Standard.

|

Length, feet |

Tolerance |

|

4 a 6 (included) |

3/16” |

|

6 a 8 (included) |

¼” |

|

8 a 10 (included) |

5/16” |

Method of measurement: According to ASTM A1030/A1030M Standard: Practice for Measuring Flatness Characteristics of Steel Sheet Products

|

Thickness, inches |

Width, inches |

Tolerance of flatness |

|||

|

Minumum yield strength, ksi |

|||||

|

Less than 45 |

45 to 55 |

55 to 80 |

80 to 100 |

||

|

0.057 a 0.18 exclusive (1/16, 1/8, 3/32) |

12 a 60 incl. |

1 ½ |

2 ¼ |

2 ½ |

2 ¾ |

|

60 a 72 incl. (6 feet) |

2 ¼ |

3 3/8” |

3 ½” |

3 ¾” |

|

|

> 72 incl. (7, 8 y 10 feet) |

3 |

4 ½ |

4 ¾ |

5 |

|

|

0.18 a 0.23 exclusive (3/16”) |

12 a 60 incl. |

1 ½ |

2 ¼ |

2 ¼ |

2 ¾ |

|

60 a 72 incl. (6 feet) |

2 ¼ |

3 3/8 |

3 3/8 |

3 ¾ |

|

|

>72 (7, 8 y 10 pies) |

3 |

4 ½ |

4 ½ |

5 |

|

Out of square

The out-of-square tolerance must be according to what is indicated in table 11 of the ASTM A568 standard.Out of square is the greatest deviation of the end of the edge from a straight line at right angles to one side touching the corner. It is also obtained by measuring the difference of diagonals. The out of square is half of this difference:The maximum out of square should be 1/16” per 6 inches width, that means, 1/8” / feet of width.

Measurement method: Direct measurement with tape measure

|

Width, feet |

Out of square, inches |

|

3 |

0.375 |

|

4 |

0.5 |

Chemical Composition

According to ASTM A36 Standard

|

Element |

Maximum concentration (w/w) |

|

C |

0.26 |

|

Mn |

N/A |

|

P |

0.04 |

|

S |

0.05 |

|

Si, max |

0.40 |

Mechanical characteristicas

The sheet must meet the mechanical requirements of grade 36 as indicated in the following table:

|

Characteristic |

Specification |

|

Yield strength, psi [MPa] |

36000 [250] |

|

Tensile strength, psi [MPa] |

58000 – 80000 [400 – 550] |

|

Elongation in 8 inches, % |

20% |

Your email address will not be published. Required fields are marked with *

Their products are of excellent quality and they offer generous discounts. This is their third cooperation