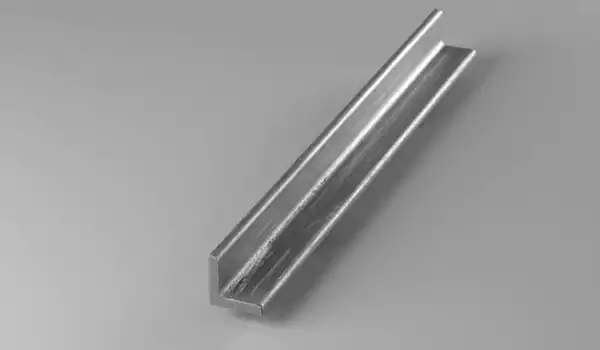

A-36 GR50 Angle Steel 1-1/4

SPECIFICATIONS: ASTM A36 Steel, Hot Rolled, Carbon Steel FINISH: Blue / Gray, Slightly grainy MECHANICAL PROPERTIES Yield Point: 36,000 psi Tensile Strength: 58-80,000 psi Elongation = 23% in 2" Elasticity = 29,000 psi Brinell Hardness = 119-158 Machinability Rate = 72% CHEMICAL PROPERTIES 98% Iron, .25-.29% Carbon, .20% Copper, .04% max Silicon, .60 - .90% Manganese, .04% Phosphorous, .05% Sulfur TOLERANCES AVAILABLE LENGTHS 2' 4' 6' 8' 10' 20' Custom Lengths

Dimensional Tolerances for Equal and Unequal Angle Steel

|

Dimension Category |

Symbol |

Tolerance (Equal Angles) |

Tolerance (Unequal Angles) |

Measurement Specifications |

|

Leg Length |

L |

- L ≤ 75mm: ±1.0mm |

- Longer leg (L₁): Same as equal angles |

Measured from the outer edge to the heel (inside corner) at both ends of the angle; average of 4 readings |

|

Leg Thickness |

t |

- t ≤ 10mm: ±10% of nominal t |

Same as equal angles |

Measured at 3 points along the leg length (1/4, 1/2, 3/4 positions) using a micrometer (accuracy ±0.01mm) |

|

Root Radius |

r |

+0.8mm / -0mm (all sizes) |

Same as equal angles |

Measured with a radius gauge (class ZZ) at the heel (inside corner) where legs meet |

|

Toe Radius |

rₜ |

+0.5mm / -0mm (all sizes) |

Same as equal angles |

Measured at the outer corners (toes) of both legs using a radius gauge |

|

Length of Angle |

Lₜ |

- Random length (6-12m): +150mm / -0mm |

Same as equal angles |

Measured with a steel tape (accuracy ±1mm/m) from end to end; includes any end shearing allowances |

|

Squareness of Legs |

- |

90° ±1° (for legs ≤100mm); 90° ±1.5° (for legs >100mm) |

Same as equal angles |

Measured with a protractor (accuracy ±0.1°) at both ends; average of 2 readings |

Straightness and Flatness Tolerances

|

Tolerance Type |

A36 and GR50 Angles |

Testing Method |

|

Lengthwise Straightness |

≤ 1.5mm/m (total straightness: ≤ 1.5×Lₜ mm, where Lₜ = total length in meters) |

Place angle on a flat surface; measure maximum gap between angle and surface with a feeler gauge |

|

Leg Flatness |

≤ 0.6mm per 100mm of leg length (max. 3mm for legs >500mm) |

Place a straightedge (grade 1, length ≥300mm) along the leg; measure gap at mid-length |

|

Twist |

≤ 1.0mm per 300mm of length (max. 5mm for total length ≤6m) |

Lay angle on a flat surface; measure maximum height of one leg relative to the surface at 300mm intervals |

|

End Squareness |

≤ 1.5mm (for leg length ≤100mm); ≤ 2.0mm (for leg length >100mm) |

Place a square against the end face; measure gap between square and end with a feeler gauge |

Notes:

All tolerances apply to hot-rolled angle steel in the as-delivered condition. For galvanized angles, additional tolerance for zinc coating thickness (70-100μm) should be considered for dimensional checks.

GR50 (ASTM A572 Grade 50) angles have the same dimensional tolerances as A36 angles, as specified in ASTM A6/A6M-24 (general requirements for structural steel shapes).

Tolerances for special sizes (leg length >300mm or thickness >25mm) may vary—consult the manufacturer for custom specifications.

Measurement should be conducted at room temperature (20℃±5℃) to avoid thermal expansion effects on dimensional accuracy.

Leg thickness tolerances are critical for load-bearing calculations; ensure measurements are taken at least 25mm from the ends to avoid edge deformation.

Chemical Composition of A36 and GR50 (ASTM A572 Grade 50) Angle Steel (Mass Fraction, %)

|

Element |

A36 (ASTM A36/A36M-24) |

GR50 (ASTM A572/A572M-24 Grade 50) |

Key Function of Element |

|

C (Carbon) |

≤ 0.25 |

≤ 0.23 |

Enhances strength; controlled to avoid brittleness (lower limit for GR50 supports weldability) |

|

Si (Silicon) |

≤ 0.40 |

≤ 0.40 |

Deoxidizer; improves strength without significant ductility loss |

|

Mn (Manganese) |

0.85–1.20 |

1.00–1.60 |

Boosts tensile strength and hardenability; higher range for GR50 to achieve superior strength |

|

P (Phosphorus) |

≤ 0.040 |

≤ 0.035 |

Strictly limited (lower for GR50) to prevent cold brittleness and improve toughness |

|

S (Sulfur) |

≤ 0.050 |

≤ 0.035 |

Minimized to reduce weld defects (e.g., hot cracking) and enhance ductility |

|

Cu (Copper) |

≥ 0.20 (optional) |

≥ 0.20 (optional) |

Improves atmospheric corrosion resistance (supplementary for outdoor applications) |

|

Cr (Chromium) |

≤ 0.30 (max, if present) |

≤ 0.30 (max, if present) |

Trace element; no negative impact on weldability or mechanical properties |

|

Ni (Nickel) |

≤ 0.30 (max, if present) |

≤ 0.30 (max, if present) |

Enhances low-temperature toughness; controlled to avoid cost escalation |

|

V (Vanadium) |

— (not specified) |

0.01–0.06 |

Critical for GR50: refines grain structure and improves yield strength without ductility loss |

|

Nb (Niobium) |

— (not specified) |

0.005–0.05 |

Optional for GR50: works with V to stabilize grain size and enhance strength |

|

Ti (Titanium) |

— (not specified) |

0.005–0.04 |

Optional for GR50: alternative to Nb for grain refinement and strength improvement |

|

N (Nitrogen) |

≤ 0.015 |

≤ 0.015 |

Stabilized by Ti/Nb in GR50 to prevent aging brittleness |

Mechanical Properties of A36 and GR50 (ASTM A572 Grade 50) Angle Steel

|

Property |

A36 (ASTM A36/A36M-24) |

GR50 (ASTM A572/A572M-24 Grade 50) |

Test Standard/Method |

Application Relevance |

|

Yield Strength (Rp0.2, ≥) |

250 MPa |

345 MPa |

ASTM E8/E8M (tensile test) |

GR50’s higher yield strength enables lighter designs for load-bearing structures |

|

Tensile Strength (Rm) |

400–550 MPa |

450–620 MPa |

ASTM E8/E8M (tensile test) |

Wider range for GR50 accommodates strength variations while maintaining performance |

|

Elongation After Fracture (A, ≥) |

20% (for t ≤ 19mm) |

18% (for t ≤ 19mm) |

ASTM E8/E8M (gauge length: 50mm) |

Slightly lower elongation for GR50 is acceptable, as it still meets ductility needs for structural use |

|

Impact Absorption Energy (KV2) |

≥ 27 J (room temp, optional) |

≥ 34 J (-40℃, optional for Grade 50J) |

ASTM A370 (Charpy V-notch test) |

GR50 offers optional low-temperature toughness (Grade 50J) for cold-climate applications |

|

Hardness (Brinell, HB) |

≤ 170 HB |

≤ 200 HB |

ASTM E10 (Brinell hardness test) |

Higher hardness for GR50 aligns with its superior strength; no impact on machinability |

|

Weldability |

Excellent (no preheat needed for t ≤ 25mm) |

Excellent (preheat recommended for t > 25mm) |

AWS D1.1 (structural welding code) |

Both grades are weldable; GR50 may require mild preheat for thick sections to prevent cracking |

|

Fatigue Strength (10⁷ cycles) |

~170 MPa |

~200 MPa |

ASTM E466/E466M (fatigue test) |

GR50’s higher fatigue strength suits dynamic load applications (e.g., bridges, machinery) |

Notes:

All values comply with the latest ASTM standards (as of 2024). For angle steel with leg thickness (t) > 19mm, mechanical properties (e.g., elongation, impact energy) may have slight adjustments—refer to ASTM A36/A36M or A572/A572M supplements.

GR50 (ASTM A572 Grade 50) is a high-strength low-alloy (HSLA) steel, while A36 is a carbon structural steel. The key difference lies in alloying elements (V, Nb, Ti) and higher strength for GR50.

For corrosive environments (e.g., marine, industrial), both grades can be hot-dip galvanized. The zinc coating (70–100μm thickness) adds corrosion resistance but does not alter the base metal’s chemical composition or mechanical properties.

Tensile and impact tests are performed on transverse specimens (relative to the hot-rolling direction) to reflect real-world structural performance under load.

Your email address will not be published. Required fields are marked with *

Their products are of excellent quality and they offer generous discounts. This is their third cooperation