S275JR S355JR Steel Profile C Shape Channel/UPN 80/100

C-Section Steel (C-Beam)

C-section steel, commonly known as C-beam or C-channel, is a high-efficiency, lightweight structural steel product characterized by its distinctive C-shaped cross-section. Primarily manufactured via cold forming (with hot rolling for specialized heavy-duty variants), it balances strength, material efficiency, and dimensional precision—making it a preferred choice in modern steel structures, construction, and manufacturing.

Cold Forming (Primary Process): Flat steel strips (usually with a thickness of 0.8–6mm) are continuously bent into a C-shape at room temperature using roll-forming equipment. This process ensures precise dimensions, smooth surfaces, and consistent mechanical properties without compromising the steel’s internal structure.

Hot Rolling (Specialized Process): Used for heavy-duty C-sections (thickness >6mm). Heated steel billets are rolled into the C-profile, delivering higher load-bearing capacity for industrial-grade applications.

Key Performance Characteristics

High Material Efficiency: The C-shape concentrates steel in high-stress areas (flanges and web), minimizing material usage while maintaining strength. Compared to traditional hot-rolled channel steel of equal weight, its section modulus (a measure of bending stiffness) is 30–50% higher.

Excellent Bending & Torsional Rigidity: Lipped cold-formed C-sections, in particular, leverage the "lip effect" to resist twisting and flange buckling, making them ideal for long-span purlins or rafters in steel buildings.

Dimensional Precision & Customization: Cold roll-forming allows flexible adjustment of web height (50–400mm), flange width (20–150mm), and thickness (0.8–6mm) without mold changes, supporting custom sizes for specific projects.

Superior Fabricability: Its regular profile facilitates easy processing—cutting (laser, plasma, sawing), drilling, punching, and welding. It can be quickly connected to other components (e.g., bolts, brackets, or gusset plates) using standard tools.

Lightweight & Easy Installation: Cold-formed C-sections are significantly lighter than hot-rolled channels of equivalent strength, reducing transportation costs and simplifying on-site lifting/assembly.

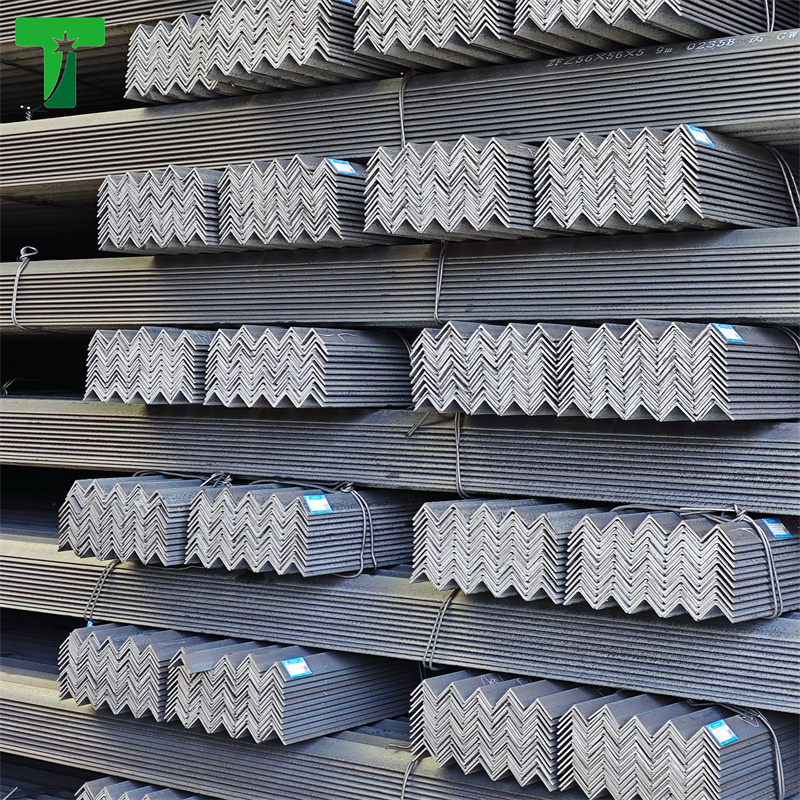

L Shapes (Equal leg)

|

|

Length of leg (mm) |

Thickness (mm) |

|||||||||

|

Producto |

Calidad |

Mín 团 |

Nom |

Máx |

Mín |

Nom |

Máx |

|

|

|

|

|

PERFIL ANGULAR 3/4"X1/8"X6M |

Legítimo |

18.26 |

19.05 |

19.84 |

2.97 |

3.18 |

3.38 |

|

|

|

|

|

PERFIL ANGULAR 3/4"X1/8X6MC |

Comercial |

18.26 |

19.05 |

19.84 |

2.00 |

2.20 |

2.40 |

|

|

|

|

|

PERFIL ANGULAR 3/4"X1/8X6M R |

Milimétrico |

18.26 |

19.05 |

19.84 |

2.60 |

2.70 |

2.80 |

|

|

|

|

|

PERFIL ANGULAR 1"X1/4"X6M |

Legítimo |

24.61 |

25.40 |

26.19 |

6.10 |

6.35 |

6.60 |

|

|

|

|

|

PERFIL ANGULAR 1"X1/8"X6M |

Legítimo |

24.61 |

25.40 |

26.19 |

2.97 |

3.18 |

3.38 |

|

|

|

|

|

PERFIL ANGULAR 1"X3/16"X6M |

Legítimo |

24.61 |

25.40 |

26.19 |

4.56 |

4.76 |

4.97 |

|

|

|

|

|

PERFIL ANGULAR 1"X1/8"X6MC |

Comercial |

24.61 |

25.40 |

26.19 |

2.10 |

2.20 |

2.30 |

|

|

|

|

|

PERFIL ANGULAR 1"X1/8X6M R |

Milimétrico |

24.61 |

25.40 |

26.19 |

2.60 |

2.70 |

2.80 |

|

|

|

|

|

PERFIL ANGULAR 1 1/4"X1/8X6MC |

Comercial |

30.51 |

31.75 |

32.89 |

2.10 |

2.20 |

2.30 |

|

|

|

|

|

PERFIL ANGULAR 1 1/4"X1/8X6M R |

Milimétrico |

30.51 |

31.75 |

32.89 |

2.60 |

2.70 |

2.80 |

|

|

|

|

|

PERFIL ANGULAR 1 1/4"X1/8"X6M |

Legítimo |

30.56 |

31.75 |

32.94 |

2.92 |

3.18 |

3.43 |

|

|

|

|

|

PERFIL ANGULAR 1 1/4"X3/16"X6M |

Legítimo |

30.56 |

31.75 |

32.94 |

4.51 |

4.76 |

5.02 |

|

|

|

|

|

PERFIL ANGULAR 1 1/4"X1/4"X6M |

Legítimo |

30.56 |

31.75 |

32.94 |

6.10 |

6.35 |

6.60 |

|

|

|

|

|

PERFIL ANGULAR 1 1/2"X1/8"X6M |

Legítimo |

36.91 |

38.10 |

39.29 |

2.92 |

3.18 |

3.43 |

|

|

|

|

|

PERFIL ANGULAR 1 1/2"X3/16"X6M |

Legítimo |

36.91 |

38.10 |

39.29 |

4.51 |

4.76 |

5.02 |

|

|

|

|

|

PERFIL ANGULAR 1 1/2"X1/4"X6M |

Legítimo |

36.91 |

38.10 |

39.29 |

6.10 |

6.35 |

6.60 |

|

|

|

|

|

PERFIL ANGULAR 1 1/2"X1/8X6M R |

Milimétrico |

36.91 |

38.10 |

39.29 |

2.60 |

2.70 |

2.80 |

|

|

|

|

|

PERFIL ANGULAR 1 1/2"X1/8X6MC |

Comercial |

36.91 |

38.10 |

39.29 |

2.10 |

2.20 |

2.30 |

|

|

|

|

|

PERFIL ANGULAR 1 1/2"X3/16X6M R |

Milimétrico |

36.91 |

38.10 |

39.29 |

3.90 |

4.00 |

4.10 |

|

|

|

|

|

PERFIL ANGULAR 2"X1/8"X6M R |

Milimétrico |

49.00 |

50.80 |

51.60 |

2.60 |

2.70 |

2.80 |

|

|

|

|

|

PERFIL ANGULAR 2"X1/8"X6M |

Legítimo |

49.61 |

50.80 |

51.99 |

2.92 |

3.18 |

3.43 |

|

|

|

|

|

PERFIL ANGULAR 2"X3/16"X6M |

Legítimo |

49.61 |

50.80 |

51.99 |

4.51 |

4.76 |

5.02 |

|

|

|

|

|

PERFIL ANGULAR 2"X1/4"X6M |

Legítimo |

49.61 |

50.80 |

51.99 |

6.10 |

6.35 |

6.60 |

|

|

|

|

|

PERFIL ANGULAR 2"X3/8"X6M |

Legítimo |

49.61 |

50.80 |

51.99 |

9.27 |

9.53 |

9.78 |

|

|

|

|

|

PERFIL ANGULAR 2 1/2"X3/16"X6M |

Legítimo |

61.91 |

63.50 |

65.09 |

4.46 |

4.76 |

5.07 |

|

|

|

|

|

PERFIL ANGULAR 2 1/2"X1/4"X6M |

Legítimo |

61.91 |

63.50 |

65.09 |

5.97 |

6.35 |

6.73 |

|

|

|

|

|

PERFIL ANGULAR 2 1/2"X3/8"X6M |

Legítimo |

61.91 |

63.50 |

65.09 |

9.14 |

9.53 |

9.91 |

|

|

|

|

|

PERFIL ANGULAR 3"X3/16"X6M |

Legítimo |

73.82 |

76.20 |

79.38 |

4.4577 |

4.76 |

5.0673 |

|

|

|

|

|

PERFIL ANGULAR 3"X1/4"X6M |

Legítimo |

73.82 |

76.20 |

79.38 |

2.41935 |

6.35 |

6.731 |

|

|

|

|

|

PERFIL ANGULAR 3"X1/2"X6M |

Legítimo |

73.82 |

76.20 |

79.38 |

No esp. |

12.70 |

No esp. |

|

|

|

|

|

PERFIL ANGULAR 3"X3/8"X6M |

Legítimo |

73.82 |

76.20 |

79.38 |

No esp. |

9.53 |

No esp. |

|

|

|

|

|

PERFIL ANGULAR 4"X1/4"X6M |

Legítimo |

99.22 |

101.60 |

104.78 |

No esp. |

6.35 |

No esp. |

|

|

|

|

|

PERFIL ANGULAR 4"X3/8"X6M |

Legítimo |

99.22 |

101.60 |

104.78 |

No esp. |

9.53 |

No esp. |

|

|

|

|

|

PERFIL ANGULAR 4"X1/2"X6M |

Legítimo |

99.22 |

101.60 |

104.78 |

No esp. |

12.70 |

No esp. |

|

|

|

|

Measurement method: Trace reference material from end to end and measure between the reference material and the shape at its greatest distance.

|

Product |

Width |

Maximum straightness, mm |

|

|

L Shape |

< 3 inches |

25 mm |

|

|

≥3 inches |

12.5 mm |

|

|

|

Round bar |

|

25 mm |

|

|

Square bar |

|

25 mm |

|

|

Flat |

|

25 mm |

|

|

T Shape |

|

25 mm |

|

|

C Shape |

|

25 mm |

|

|

Yield point, psi (Autographic Diagram Method according to ASTM A370 standard) |

36,000 |

|

Tensile strength, psi |

58,000 - 80,000 |

|

Elongation in 8 in, % |

20 |

De acuerdo a lo establecido en la norma ASTM A36

|

Element |

Specification |

|

C |

0.26 |

|

Mn |

|

|

P |

0.04 |

|

S |

0.05 |

|

Si, máx |

0.40 |

According to ASTM A6 Standard, Structural products shall be free of injurious

defects and shall have a workmanlike finish.

Free of rust

Cut: straight cut

Tie with strapping or wire rod

Protected to prevent rust in transport

Quality certificate must include heat number, chemical composition, tensile test results

Your email address will not be published. Required fields are marked with *

Their products are of excellent quality and they offer generous discounts. This is their third cooperation