High-Temp ASTM A672 Welded Pipes: C60-C90, Power Plant Use

Premium Welded Steel Pipes: 18 Years of Trusted Global Supply Excellence

Tailored for industrial buyers worldwide—combining 18-year export expertise, strict quality compliance, and cost-effective solutions to power your projects.

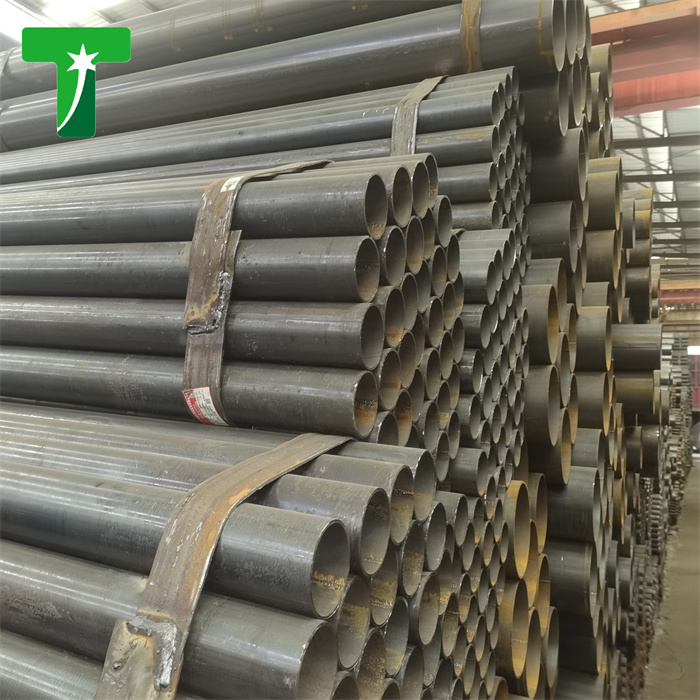

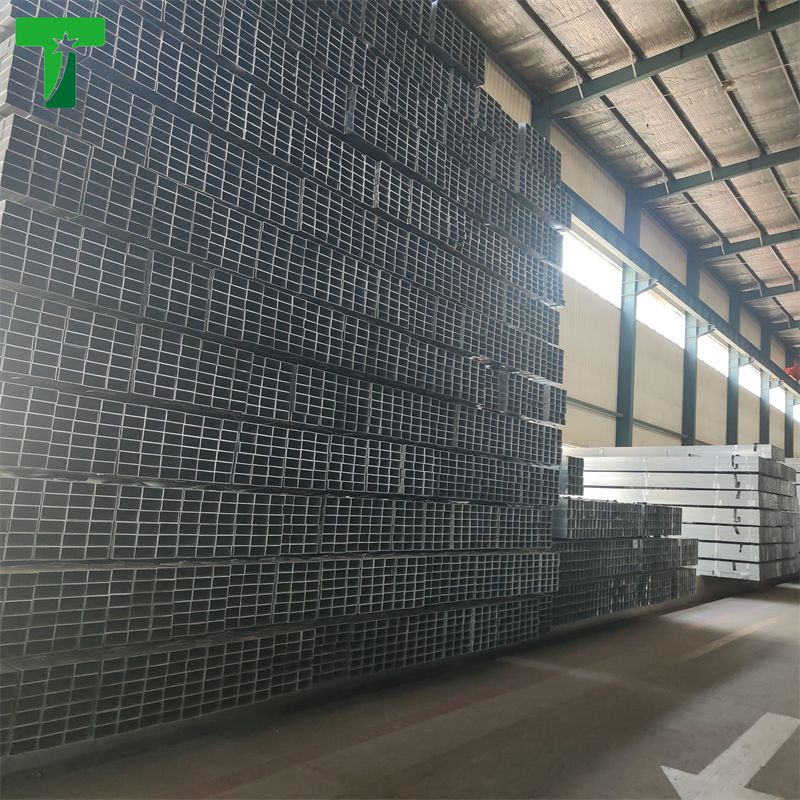

What Are Welded Steel Pipes?

Welded steel pipes are high-performance tubular products crafted by bending steel sheets into cylindrical shapes, then joining seams via ERW (Electric Resistance Welding) or SAW (Submerged Arc Welding).

Compared to seamless pipes, they deliver:

20-30% lower costs for large-scale orders

Ultra-precise dimensions (±0.1mm tolerance)

High tensile strength (up to 700 MPa)

Making them a must-have for industrial projects requiring reliability and efficiency.

International Grade Portfolio

|

Global Size Compatibility

Fully aligned with ASME B36.10, DIN 2448, and ISO 4200 standards—no adaptation needed for international projects:

Outer Diameter (OD): 12.7mm (1/2") to 1600mm (63") – covers micro-pipes to large-diameter industrial tubes

Wall Thickness: SCH10, SCH20, SCH40, SCH80, XS, XXS – customizable to ±0.05mm for special needs

End Finishes: Beveled End (BE) for welding, Threaded End (TE) for quick assembly, Plain End (PE) for custom connections – all pre-treated for rust prevention.

Cross-Industry Applications

Trusted by 5000+ clients in 60+ countries for critical scenarios:

Municipal Infrastructure: Potable water distribution, sewage treatment (ASTM A53 – 50-year service life)

Offshore Energy: Deep-sea oil/gas platform pipelines (API 5L X70 – anti-salt corrosion, anti-wave impact)

Advanced Manufacturing: Machinery shafts, pressure storage tanks (ASTM A312 316L – food-grade, non-toxic)

Renewable Energy: Wind turbine towers, solar power plant supports (carbon steel – high load-bearing, anti-fatigue)

18-Year Export Advantages: Why Choose Us Over Competitors?

Factory-Direct Cost Savings: Skip middlemen to cut 30% of procurement costs—we own 3 production bases (annual capacity 500,000 tons) for bulk raw material sourcing.

Rapid Turnaround: 7-day sample delivery for custom grades/sizes; 10-15 days for standard orders (2x faster than industry average).

Global Compliance Mastery: We don’t just "meet" standards—we specialize in regional requirements:

EU: CE (EN 10217-1), REACH

USA: API 5L Monogram, ASTM certification

Asia: JIS G3452, GB/T 3091

Risk-Free After-Sales: 12-month quality warranty; if defects occur (we have a 0.01% defect rate), we offer free replacements + on-site technical support.

FAQ: Solve Your Top Concerns

Q1: How do you guarantee weld seam quality—critical for high-pressure projects?

A: Every pipe undergoes 3-tier testing: 100% automated ultrasonic testing (to detect micro-cracks), hydrostatic pressure testing (up to 200 bar, 30 minutes), and visual inspection (per API 5L Annex H). We provide a test report for each batch—traceable via QR code.

Q2: What’s the minimum order quantity (MOQ) for custom sizes?

A: Only 5 tons for standard grades (e.g., API 5L X42); for long-term clients (6+ months cooperation), MOQ is negotiable to 2 tons—perfect for small-batch trial projects.

Q3: Can you handle door-to-door delivery to remote locations (e.g., Africa, South America)?

A: Yes! We partner with Maersk, COSCO, and DHL for FOB, CIF, DDP, DAP terms. We manage customs clearance (all documents prepared in 24 hours) and last-mile delivery—98% of orders arrive on time (average delay <1 day).

Ready to Get Started?

Click "Get Free Quote" now—our technical team will send a customized solution (including material selection, size recommendation, and logistics plan) within 4 hours.

Your project deserves pipes that combine strength, compliance, and value—we deliver exactly that.

|

O.D. |

W.T. |

Length(m) |

|||||||

|

Inch |

mm |

Min.Yield Strength(Mpa) |

|||||||

|

Inch |

mm |

245(B) |

290(X42) |

360(X52) |

415(X60) |

450(X65) |

485(X70) |

555(X80) |

|

|

16 |

406 |

6.0-14.0 |

6.0-13.0 |

6.0-12.0 |

6.0-11.0 |

6.0-10.5 |

6.0-10.0 |

6.0-9.0 |

6.0-12.3 |

|

18 |

457 |

6.0-15.0 |

6.0-14.0 |

6.0-13.0 |

6.0-12.0 |

6.0-11.5 |

6.0-11.0 |

6.0-10.0 |

6.0-12.3 |

|

20 |

508 |

6.0-16.0 |

6.0-15.0 |

6.0-14.0 |

6.0-13.0 |

6.0-12.5 |

6.0-12.0 |

6.0-11.0 |

6.0-12.3 |

|

22 |

559 |

6.0-17.0 |

6.0-16.0 |

6.0-15.0 |

6.0-14.0 |

6.0-13.5 |

6.0-13.0 |

6.0-12.0 |

6.0-12.3 |

|

24 |

610 |

6.0-18.0 |

6.0-17.0 |

6.0-16.0 |

6.0-15.0 |

6.0-14.5 |

6.0-14.0 |

6.0-13.0 |

6.0-12.3 |

|

26 |

660 |

6.0-19.0 |

6.0-18.0 |

6.0-17.0 |

6.0-16.0 |

6.0-15.0 |

6.0-15.0 |

6.0-14.0 |

6.0-12.3 |

|

28 |

711 |

6.0-20.0 |

6.0-19.0 |

6.0-18.0 |

6.0-17.0 |

6.0-16.5 |

6.0-16.0 |

6.0-15.0 |

6.0-12.3 |

|

30 |

762 |

7.0-21.0 |

7.0-20.0 |

7.0-19.0 |

7.0-18.0 |

7.0-17.5 |

7.0-17.0 |

7.0-16.0 |

6.0-12.3 |

|

32 |

813 |

7.0-22.0 |

7.0-21.0 |

7.0-20.0 |

7.0-19.0 |

7.0-18.5 |

7.0-18.0 |

7.0-17.0 |

6.0-12.3 |

|

34 |

864 |

7.0-23.0 |

7.0-22.0 |

7.0-21.0 |

7.0-20.0 |

7.0-19.5 |

7.0-19.0 |

7.0-18.0 |

6.0-12.3 |

|

36 |

914 |

8.0-24.0 |

8.0-23.0 |

8.0-22.0 |

8.0-21.0 |

8.0-20.5 |

8.0-20.0 |

8.0-19.0 |

6.0-12.3 |

|

38 |

965 |

8.0-25.0 |

8.0-24.0 |

8.0-23.0 |

8.0-22.0 |

8.0-21.5 |

8.0-21.0 |

8.0-20.0 |

6.0-12.3 |

|

40 |

1016 |

8.0-26.0 |

8.0-25.0 |

8.0-24.0 |

8.0-23.0 |

8.0-22.5 |

8.0-22.0 |

8.0-21.0 |

6.0-12.3 |

|

42 |

1067 |

8.0-26.0 |

8.0-25.0 |

8.0-24.0 |

8.0-23.0 |

8.0-22.5 |

8.0-22.0 |

8.0-21.0 |

6.0-12.3 |

|

44 |

1118 |

9.0-27.0 |

9.0-26.0 |

9.0-24.5 |

9.0-23.5 |

9.0-22.8 |

9.0-22.0 |

9.0-21.0 |

6.0-12.3 |

|

46 |

1168 |

9.0-27.0 |

9.0-26.0 |

9.0-24.0 |

9.0-23.5 |

9.0-22.8 |

9.0-22.0 |

9.0-21.0 |

6.0-12.3 |

|

48 |

1219 |

9.0-28.0 |

9.0-27.0 |

9.0-25.4 |

9.0-24.0 |

9.0-23.5 |

9.0-23.0 |

9.0-22.0 |

6.0-12.3 |

|

52 |

1321 |

9.0-28.0 |

9.0-27.0 |

9.0-25.4 |

9.0-24.2 |

9.0-23.5 |

9.0-23.0 |

9.0-22.0 |

6.0-12.3 |

|

56 |

1422 |

10.0-29.0 |

10.0-28.0 |

10.0-26.0 |

10.0-24.5 |

10.0-23.8 |

10.0-23.0 |

10.0-22.0 |

6.0-12.3 |

|

60 |

1524 |

10.0-29.0 |

10.0-28.0 |

10.0-26.0 |

10.0-24.5 |

10.0-23.8 |

10.0-23.0 |

10.0-22.0 |

6.0-12.3 |

|

64 |

1626 |

10.0-30.0 |

10.0-29.0 |

10.0-27.0 |

10.0-25.4 |

10.0-24.8 |

10.0-24.0 |

10.0-23.0 |

6.0-12.3 |

|

68 |

1727 |

10.0-30.0 |

10.0-29.0 |

10.0-27.0 |

10.0-25.4 |

10.0-24.8 |

10.0-24.0 |

10.0-23.0 |

6.0-12.3 |

|

72 |

1829 |

10.0-30.0 |

10.0-29.0 |

10.0-27.0 |

10.0-25.4 |

10.0-24.8 |

10.0-24.0 |

10.0-23.0 |

6.0-12.3 |

Tolerance of Outside Diameter and Wall Thickness

|

Types |

Standard |

|||||

|

SY/T5040-2000 |

SY/T5037-2000 |

SY/T9711.1-1977 |

ASTM A252 |

AWWA C200-97 |

API 5L PSL1 |

|

|

Tube end OD deviation |

±0.5%D |

±0.5%D |

-0.79mm~+2.38mm |

<±0.1%T |

<±0.1%T |

±1.6mm |

|

Wall thickness |

±10.0%T |

D<508mm, ±12.5%T |

-8%T~+19.5%T |

<-12.5%T |

-8%T~+19.5%T |

5.0mm |

|

D>508mm, ±10.0%T |

T≥15.0mm, ±1.5mm |

|||||

Chemical Composition and Mechanical Properties

|

Standard |

Grade |

Chemical Composition(max)% |

Mechanical Properties(min) |

|||||

|

C |

Mn |

Si |

S |

P |

Yield Strength(Mpa) |

Tensile Strength(Mpa) |

||

|

GB/T700-2006 |

A |

0.22 |

1.4 |

0.35 |

0.050 |

0.045 |

235 |

370 |

|

B |

0.2 |

1.4 |

0.35 |

0.045 |

0.045 |

235 |

370 |

|

|

C |

0.17 |

1.4 |

0.35 |

0.040 |

0.040 |

235 |

370 |

|

|

D |

0.17 |

1.4 |

0.35 |

0.035 |

0.035 |

235 |

370 |

|

|

GB/T1591-2009 |

A |

0.2 |

1.7 |

0.5 |

0.035 |

0.035 |

345 |

470 |

|

B |

0.2 |

1.7 |

0.5 |

0.030 |

0.030 |

345 |

470 |

|

|

C |

0.2 |

1.7 |

0.5 |

0.030 |

0.030 |

345 |

470 |

|

|

BS En10025 |

S235JR |

0.17 |

1.4 |

- |

0.035 |

0.035 |

235 |

360 |

|

S275JR |

0.21 |

1.5 |

- |

0.035 |

0.035 |

275 |

410 |

|

|

S355JR |

0.24 |

1.6 |

- |

0.035 |

0.035 |

355 |

470 |

|

|

DIN 17100 |

ST37-2 |

0.2 |

- |

- |

0.050 |

0.050 |

225 |

340 |

|

ST44-2 |

0.21 |

- |

- |

0.050 |

0.050 |

265 |

410 |

|

|

ST52-3 |

0.2 |

1.6 |

0.55 |

0.040 |

0.040 |

345 |

490 |

|

|

JIS G3101 |

SS400 |

- |

- |

- |

0.050 |

0.050 |

235 |

400 |

|

SS490 |

- |

- |

- |

0.050 |

0.050 |

275 |

490 |

|

|

API 5L PSL1 |

A |

0.22 |

0.9 |

- |

0.03 |

0.03 |

210 |

335 |

|

B |

0.26 |

1.2 |

- |

0.03 |

0.03 |

245 |

415 |

|

|

X42 |

0.26 |

1.3 |

- |

0.03 |

0.03 |

290 |

415 |

|

|

X46 |

0.26 |

1.4 |

- |

0.03 |

0.03 |

320 |

435 |

|

|

X52 |

0.26 |

1.4 |

- |

0.03 |

0.03 |

360 |

460 |

|

|

X56 |

0.26 |

1.1 |

- |

0.03 |

0.03 |

390 |

490 |

|

|

X60 |

0.26 |

1.4 |

- |

0.03 |

0.03 |

415 |

520 |

|

|

X65 |

0.26 |

1.45 |

- |

0.03 |

0.03 |

450 |

535 |

|

|

X70 |

0.26 |

1.65 |

- |

0.03 |

0.03 |

585 |

570 |

|

Your email address will not be published. Required fields are marked with *

Their products are of excellent quality and they offer generous discounts. This is their third cooperation