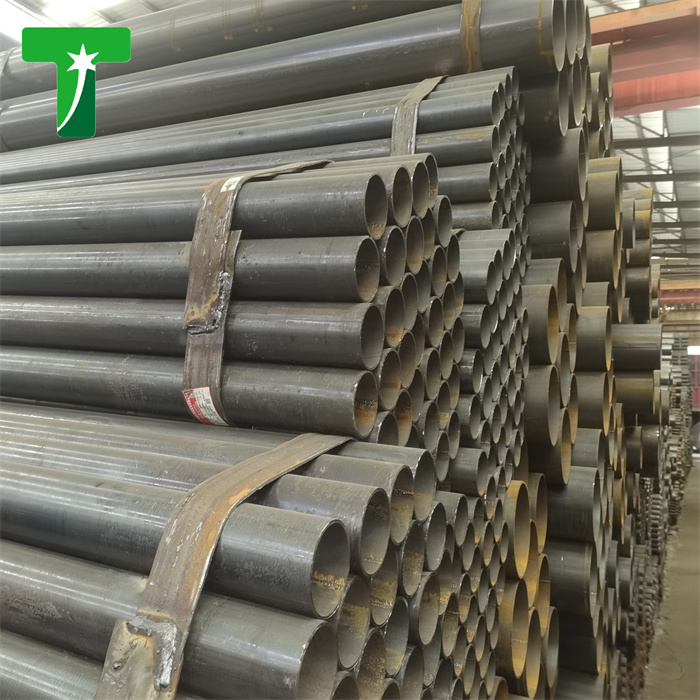

S355J2H Galvanized Steel Tubes

| Grade | S355J2 |

|---|---|

| European Standard Steel Grade | 1.0557 |

| Corresponding Standard |

EN 10025-2-2004 Hot rolled products of structural steels - Part 2:Technical delivery conditions for non-alloy structural steels |

| Classification | Carbon Steel |

Dimensional Tolerances (Before & After Galvanizing)

|

Dimension Category |

Symbol |

Tolerance (Before Galvanizing) |

Additional Tolerance for Hot-Dip Galvanizing |

Total Tolerance (After Galvanizing) |

Measurement Specifications |

|

Outside Diameter (OD) |

D |

- OD ≤ 50mm: ±0.5mm |

Uniform zinc coating thickness: 70-100μm (adds 0.07-0.10mm to OD per side) |

- OD ≤ 50mm: ±0.7mm |

Measured with a digital caliper (accuracy ±0.01mm) at 3 cross-sections (1/4, 1/2, 3/4 of tube length); avoid weld seams (for welded tubes) |

|

Inside Diameter (ID) |

d |

Same as OD tolerance (derived from OD - 2×WT) |

Zinc coating does not affect ID (coating applied externally only) |

Same as pre-galvanizing ID tolerance |

Calculated as measured OD - 2×measured WT; verify with an internal caliper for ID > 80mm |

|

Wall Thickness (WT) |

t |

- t ≤ 5mm: ±10% of nominal t |

No impact on base metal thickness (zinc coating is external) |

Same as pre-galvanizing WT tolerance |

Measured via ultrasonic thickness gauge (UTG, accuracy ±0.05mm) at 4 points (90° apart) per cross-section; ensure probe coupling with galvanized surface |

|

Tube Length (L) |

L |

- Random length (6-12m): +150mm / -0mm |

No length change from galvanizing process |

Same as pre-galvanizing length tolerance |

Measured with a steel tape (accuracy ±1mm/m) from end face to end face; ensure ends are free of zinc drips |

|

Zinc Coating Thickness |

δ |

N/A (applied post-manufacturing) |

- Minimum: 70μm (per EN 10240) |

- Minimum: 70μm |

Measured with a magnetic coating thickness gauge (accuracy ±3μm) at 5 points per m² of tube surface; include flat, curved, and weld areas (for welded tubes) |

Shape & Geometric Tolerances

|

Tolerance Type |

Pre-Galvanizing Tolerance |

Post-Galvanizing Tolerance |

Testing Method |

|

Out-of-Roundness |

≤ 1.0% of nominal OD (max. 1.5mm for OD ≤ 100mm) |

Same as pre-galvanizing (zinc coating is uniform) |

Calculate as (max. OD - min. OD) at a single cross-section; test 3 cross-sections per tube |

|

Straightness |

≤ 1.5mm/m (total straightness: ≤ 1.5×L mm, L = tube length in meters) |

Same as pre-galvanizing (galvanizing does not cause bending) |

Place tube on 2 supports (1m from each end); measure maximum deflection with a dial gauge (accuracy ±0.01mm) |

|

End Squareness |

≤ 1.0mm/m (max. 2mm for tube ends with OD ≤ 150mm) |

Same as pre-galvanizing (zinc drips may be removed to meet tolerance) |

Place a precision square (class 0) against the tube end face; measure gap with a feeler gauge (0.01-1.0mm range) |

|

Weld Seam Protrusion (Welded Tubes) |

- External: ≤ 0.5mm |

- External: ≤ 0.7mm (includes zinc coating) |

Use a weld gauge (type B) to measure protrusion at 3 points along the weld (start, middle, end) |

|

Surface Flatness (Seamless Tubes) |

No localized protrusions > 0.3mm |

No localized protrusions > 0.5mm (includes zinc coating) |

Run a straightedge (length ≥300mm, grade 1) along the tube surface; check for gaps with a feeler gauge |

Galvanized Coating Appearance Tolerances

|

Coating Defect Type |

Allowable Limit (Per EN 10240) |

Rejection Criteria |

|

Zinc Drips/Runs |

Max. height: 1.0mm; max. length: 50mm; max. 2 drips per meter of tube length |

Drips > 1.5mm in height; drips causing OD to exceed total tolerance |

|

Bare Spots |

Max. area: 25mm²; max. 2 spots per meter of tube length |

Bare spots > 50mm²; contiguous bare spots > 100mm in length |

|

Porosity |

Isolated pinholes (≤ 0.5mm diameter) allowed; no clustered porosity |

Clustered pinholes (≥3 in 100mm² area); pinholes > 1.0mm diameter |

|

Adhesion |

No flaking or peeling when tested with a sharp tool (scratch test: 90° angle, 5N force) |

Visible flaking/peeling of coating; coating detachment during handling |

Notes:

All tolerances align with EN 10210-2:2006 (for S355J2H structural steel tubes) and EN 10240:2009 (for hot-dip galvanizing). For custom requirements (e.g., tighter OD tolerance), confirm with the manufacturer.

The galvanizing process adds a uniform zinc layer to the external surface only—internal dimensions (ID, internal weld protrusion) remain unchanged from pre-galvanizing values.

For tubes used in corrosive environments (e.g., marine, industrial), verify that zinc coating thickness meets or exceeds 85μm (average) to ensure long-term corrosion resistance.

Tolerance verification must be conducted at room temperature (20℃±5℃) to avoid thermal expansion effects on dimensional measurements.

Chemical Composition of S355J2H Galvanized Steel Tubes (Mass Fraction, ≤ %)

|

Element |

Content (Base Metal, per EN 10210-2:2006) |

Note on Zinc Coating (Hot-Dip Galvanizing, per EN 10240:2009) |

|

C (Carbon) |

≤ 0.20 |

No carbon in zinc coating; coating does not alter base metal C content |

|

Si (Silicon) |

≤ 0.55 |

Silicon may slightly affect galvanizing reactivity (controlled to avoid uneven coating) |

|

Mn (Manganese) |

≤ 1.60 |

Enhances base metal strength; no impact on zinc coating adhesion |

|

P (Phosphorus) |

≤ 0.035 |

Strictly limited to prevent brittleness (critical for low-temperature performance) |

|

S (Sulfur) |

≤ 0.035 |

Minimized to reduce weld defects and improve ductility |

|

Cr (Chromium) |

≤ 0.30 |

Trace element; no negative effect on galvanizing process |

|

Ni (Nickel) |

≤ 0.30 |

Improves toughness; compatible with zinc coating |

|

Cu (Copper) |

≤ 0.30 |

May slightly increase coating thickness (controlled within range) |

|

Mo (Molybdenum) |

≤ 0.10 |

Trace element; enhances base metal corrosion resistance (supplementary to galvanizing) |

|

V (Vanadium) |

≤ 0.05 |

Refines grain structure; no impact on zinc coating properties |

|

N (Nitrogen) |

≤ 0.012 |

Stabilized with Ti/Nb to prevent aging brittleness |

|

Ti (Titanium) |

≤ 0.10 |

Grain refiner; improves base metal ductility |

|

Nb (Niobium) |

≤ 0.05 |

Works with Ti to stabilize nitrogen; no effect on galvanizing |

|

Zinc (Zn, Coating) |

N/A (coating composition: ≥ 98.5% pure Zn) |

Zinc coating adds corrosion resistance; no diffusion into base metal |

Mechanical Properties of S355J2H Galvanized Steel Tubes

|

Property |

Base Metal (Before Galvanizing, per EN 10210-2:2006) |

Effect of Hot-Dip Galvanizing (Post-Galvanizing) |

Test Standard/Method |

|

Yield Strength (Rp0.2) |

≥ 355 MPa |

No significant change (galvanizing temp ~450℃; below base metal recrystallization temperature) |

EN ISO 6892-1 (tensile test, transverse direction) |

|

Tensile Strength (Rm) |

470–630 MPa |

±5% variation (max.) due to minor thermal stress relief; remains within EN 10210-2 range |

EN ISO 6892-1 (tensile test on full tube or flat specimens) |

|

Elongation After Fracture (A) |

≥ 22% (for t ≤ 16mm); ≥ 20% (for 16mm < t ≤ 40mm) |

No reduction (galvanizing does not induce embrittlement in S355J2H) |

EN ISO 6892-1 (measured on gauge length L0 = 50mm) |

|

Impact Absorption Energy (KV2) |

≥ 34 J at -40℃ (low-temperature toughness requirement for J2 grade) |

No degradation (zinc coating acts as barrier; base metal toughness preserved) |

EN ISO 148-1 (Charpy V-notch test, transverse specimens) |

|

Hardness (HV10) |

≤ 230 HV (base metal) |

Base metal hardness unchanged; zinc coating hardness: 70–90 HV (softer than base metal) |

EN ISO 6507-1 (Vickers hardness test; base metal: 10kg load; coating: 1kg load) |

|

Zinc Coating Adhesion |

N/A (base metal property) |

No flaking/peeling when bent 180° around mandrel (diameter = 3×tube OD) or when scratched with 5N force |

EN 10240 (bend test and scratch test) |

|

Zinc Coating Corrosion Resistance |

N/A (base metal property) |

≥ 500 hours of neutral salt spray (NSS) without red rust (per ASTM B117) |

ASTM B117 (salt spray test); EN ISO 9227 (alternative) |

Notes:

All base metal properties comply with EN 10210-2:2006 for S355J2H structural steel tubes. Galvanizing properties follow EN 10240:2009 (hot-dip galvanizing for steel tubes).

Hot-dip galvanizing (process temp: 440–460℃) does not alter the base metal’s core mechanical properties (strength, toughness) because the temperature is below the steel’s austenitization range (~Ac1: 723℃ for S355J2H).

For tubes with wall thickness (t) > 40mm, mechanical properties (e.g., elongation, impact energy) may require adjustment—consult the manufacturer for grade-specific data.

Corrosion resistance is primarily provided by the zinc coating (cathodic protection). The base metal’s inherent corrosion resistance is supplementary; avoid removing the zinc coating during installation.

Tensile and impact tests are performed on transverse specimens (relative to the tube’s manufacturing direction) to reflect real-world load-bearing behavior.

Your email address will not be published. Required fields are marked with *

Their products are of excellent quality and they offer generous discounts. This is their third cooperation