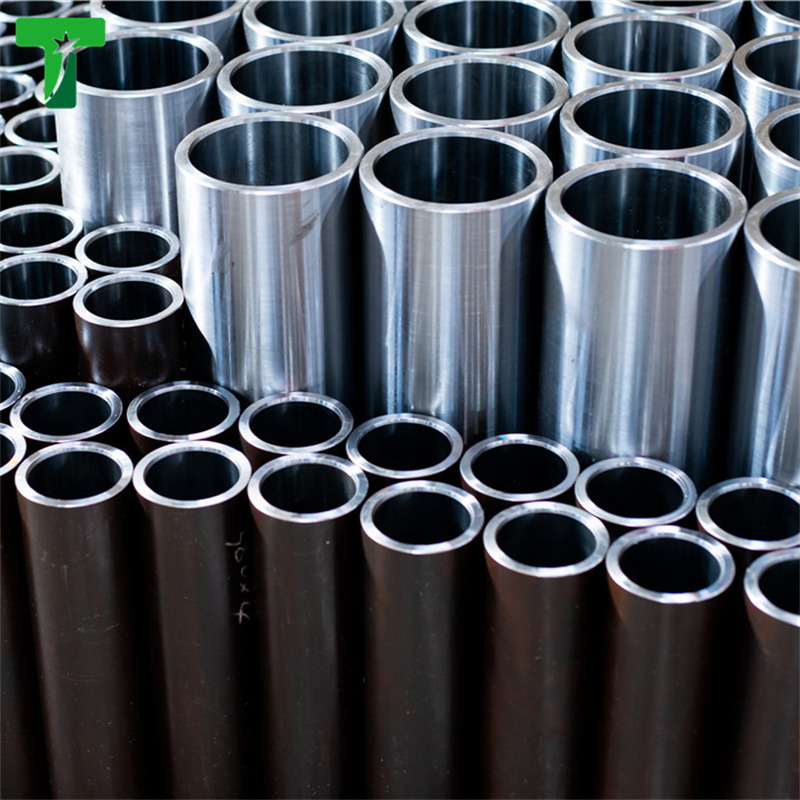

ASTM A106 Seamless Honed Tubes 12 Meters

1. Product Introduction

Seamless honed tube, also known as precision hydraulic cylinder barrel or honed tube, is a high-precision, high-finish seamless steel tube made from a cold-drawn or hot-rolled seamless steel tube as a base tube, with the inner bore processed through a precision honing process. It is the core and most critical component in the manufacturing of hydraulic and pneumatic cylinders (oil cylinders), directly determining the performance, efficiency, reliability, and service life of hydraulic/pneumatic systems.

2.Key Features of a Honing Tube:

1). Abrasive Stones: The honing tube typically contains abrasive stones that are mounted on expandable arms. These stones come in various grit sizes and materials (e.g., aluminum oxide, silicon carbide, or diamond) depending on the material being honed and the desired finish.

2).Expandable Mechanism: The honing tube often has an expandable mechanism that allows the abrasive stones to be adjusted radially to match the diameter of the bore. This ensures consistent contact and pressure between the stones and the workpiece.

3). Coolant Channels: Many honing tubes have built-in channels for coolant or honing oil to flow through. This helps to lubricate the cutting process, remove debris, and prevent overheating.

4).Drive Mechanism: The honing tube is usually attached to a honing machine or a drill, which provides the rotational and reciprocating motion necessary for the honing process.

3. Applications:

1). Automotive Industry: Honing is commonly used to finish engine cylinders, ensuring proper piston fit and lubrication.

2). Aerospace: Precision honing is used for hydraulic cylinders and other critical components.

3). Manufacturing: Honing is used in the production of various cylindrical components that require precise dimensions and smooth surfaces.

4. Advantages

1). Precision: Honing can achieve very tight tolerances and precise geometries.

2). Surface Finish: The process produces a smooth, cross-hatched surface that is ideal for lubrication.

3). Versatility: Honing can be used on a wide range of materials, including metals, ceramics, and composites.

5. Packaging and Shipping

Standard export packing. The modes of transportation include containerized sea freight, bulk sea freight, air freight, land transportation, and multi-modal transportation.

6. Q&A

Q1. who are we?

A:We are based in Tianjin China, start from 2015,sell to Southeast Asia(26.00%),Africa(8.00%),Eastern Europe(8.00%),Eastern Asia(7.00%),Western Europe(7.00%),Southern Europe(7.00%),North America(6.00%),South America(6.00%),Northern Europe(6.00%),Oceania(5.00%),Central America(5.00%),Mid East(5.00%),South Asia(4.00%). There are total about 5-10 people in our office.

Q2. how can we guarantee quality?

A:Always a pre-production sample before mass production.

Always final Inspection before shipment.

Q3. what can you buy from us?

A:Rectangle Steel Tubes, Triangular Seamless Steel Pipes, Cold Rolled High Precision Seamless Steel Pipes, Hot Rolled Seamless Steel Pipes

Q4. why should you buy from us not from other suppliers?

A: SKY STEEL CONSTRUCTION LIMITED which is a professional manufacturer more than 20 years. The main products are seamless steel pipes, galvanized steel pipe, welded steel pipe ,square&rectangular tube and scaffolding products.

Q5. what services can we provide?

A: Accepted Delivery Terms: FOB, CFR, CIF, EXW, Express Delivery.

Accepted Payment Currency: USD, EUR, CNY.

Accepted Payment Type: T/T, Credit Card, Cash, Agency.

Tolerances of carbon seamless steel pipe

|

Pipe types |

Pipe sizes(mm) |

Tolerances |

|

Hot rolled |

OD<50 |

±0.50mm |

|

|

OD≥50 |

±1% |

|

|

WT<4 |

±12.5% |

|

|

WT 4~20 |

+15%, -12.5% |

|

|

WT>20 |

±12.5% |

|

Cold drawn |

OD 6~10 |

±0.20mm |

|

|

OD 10~30 |

±0.40mm |

|

|

OD 30~50 |

±0.45 |

|

|

OD>50 |

±1% |

|

|

WT≤1 |

±0.15mm |

|

|

WT 1~3 |

+15%, -10% |

|

|

WT >3 |

+12.5%, -10% |

|

NOMINAL PIPE SIZE |

OD(mm) |

||||||||||||||

|

DN |

NB(inch) |

ASME |

SCH10 |

SCH20 |

SCH30 |

STD |

SCH40 |

SCH60 |

XS |

SCH80 |

SCH100 |

SCH120 |

SCH140 |

SCH160 |

XXS |

|

15 |

1/2" |

21.3 |

2.11 |

|

2.41 |

2.77 |

2.77 |

|

3.73 |

3.73 |

|

|

|

4.78 |

7.47 |

|

20 |

3/4" |

26.7 |

2.11 |

|

2.41 |

2.87 |

2.87 |

|

3.91 |

3.91 |

|

|

|

5.56 |

7.82 |

|

25 |

1" |

33.4 |

2.77 |

|

2.9 |

3.38 |

3.38 |

|

4.55 |

4.55 |

|

|

|

6.35 |

9.09 |

|

32 |

1.1/4" |

42.2 |

2.77 |

|

2.97 |

3.56 |

3.56 |

|

4.85 |

4.85 |

|

|

|

6.35 |

9.7 |

|

40 |

1.1/2" |

48.3 |

2.77 |

|

3.18 |

3.68 |

3.68 |

|

5.08 |

5.08 |

|

|

|

7.14 |

10.15 |

|

50 |

2" |

60.3 |

2.77 |

|

3.18 |

3.91 |

3.91 |

|

5.54 |

5.54 |

|

|

|

8.74 |

11.07 |

|

65 |

2.1/2" |

73 |

3.05 |

|

4.78 |

5.16 |

5.16 |

|

7.01 |

7.01 |

|

|

|

9.53 |

14.02 |

|

80 |

3" |

88.9 |

3.05 |

|

4.78 |

5.49 |

5.49 |

|

7.62 |

7.62 |

|

|

|

11.13 |

15.25 |

|

90 |

3.1/2" |

101.6 |

3.05 |

|

4.78 |

5.74 |

5.74 |

|

8.08 |

8.08 |

|

|

|

|

|

|

100 |

4" |

114.3 |

3.05 |

|

4.78 |

6.02 |

6.02 |

|

8.56 |

8.56 |

|

11.13 |

|

13.49 |

17.12 |

|

125 |

5" |

141.3 |

3.4 |

|

|

6.55 |

6.55 |

|

9.53 |

9.53 |

|

12.7 |

|

15.88 |

19.05 |

|

150 |

6" |

168.3 |

3.4 |

|

|

7.11 |

7.11 |

|

10.97 |

10.97 |

|

14.27 |

|

18.26 |

21.95 |

|

200 |

8" |

219.1 |

3.76 |

6.35 |

7.04 |

8.18 |

8.18 |

10.31 |

12.7 |

12.7 |

15.09 |

18.26 |

20.62 |

23.01 |

22.23 |

|

250 |

10" |

273 |

4.19 |

6.35 |

7.8 |

9.27 |

9.27 |

12.7 |

12.7 |

15.09 |

18.26 |

21.44 |

25.4 |

28.58 |

25.4 |

|

300 |

12" |

323.8 |

4.57 |

6.35 |

8.38 |

9.53 |

10.31 |

14.27 |

12.7 |

17.48 |

21.44 |

25.4 |

28.58 |

33.32 |

25.4 |

|

350 |

14" |

355.6 |

6.35 |

7.92 |

9.53 |

9.53 |

11.13 |

15.09 |

12.7 |

19.05 |

23.83 |

27.79 |

31.75 |

35.71 |

|

|

400 |

16" |

406.4 |

6.35 |

7.92 |

9.53 |

9.53 |

12.7 |

16.66 |

12.7 |

21.44 |

26.19 |

30.96 |

36.53 |

40.19 |

|

|

450 |

18" |

457.2 |

6.35 |

7.92 |

11.13 |

9.53 |

14.27 |

19.05 |

12.7 |

23.83 |

39.36 |

34.93 |

39.67 |

45.24 |

|

|

500 |

20" |

508 |

6.35 |

9.53 |

12.7 |

9.53 |

15.09 |

20.62 |

12.7 |

26.19 |

32.54 |

38.1 |

44.45 |

50.01 |

|

|

550 |

22" |

558.8 |

6.35 |

9.53 |

12.7 |

9.53 |

|

22.23 |

12.7 |

28.58 |

34.93 |

41.28 |

47.63 |

53.98 |

|

|

600 |

24" |

609.6 |

6.35 |

9.53 |

14.27 |

9.53 |

17.48 |

24.61 |

12.7 |

30.96 |

38.89 |

46.02 |

52.37 |

59.54 |

|

|

650 |

26" |

660.4 |

7.92 |

12.7 |

|

9.53 |

|

|

12.7 |

|

|

|

|

|

|

|

700 |

28" |

711.2 |

7.92 |

12.7 |

15.88 |

9.53 |

|

|

12.7 |

|

|

|

|

|

|

|

750 |

30" |

762 |

7.92 |

12.7 |

15.88 |

9.53 |

|

|

12.7 |

|

|

|

|

|

|

|

800 |

32" |

812.8 |

7.92 |

12.7 |

15.88 |

9.53 |

17.48 |

|

12.7 |

|

|

|

|

|

|

|

850 |

34" |

863.6 |

7.92 |

12.7 |

15.88 |

9.53 |

17.48 |

|

12.7 |

|

|

|

|

|

|

|

900 |

36" |

914.4 |

7.92 |

12.7 |

15.88 |

9.53 |

19.05 |

|

12.7 |

|

|

|

|

|

|

Chemical Composition and Mechanical Properties

|

Standard |

Grade |

Chemical Components (%) |

Mechanical Properties |

|||||

|

|

|

C |

Si |

Mn |

P |

S |

Tensile STrength(Mpa) |

Yield STrength(Mpa) |

|

ASTM A53 |

A |

≤0.25 |

- |

≤0.95 |

≤0.05 |

≤0.06 |

≥330 |

≥205 |

|

|

B |

≤0.30 |

- |

≤1.2 |

≤0.05 |

≤0.06 |

≥415 |

≥240 |

|

ASTM A106 |

A |

≤0.30 |

≥0.10 |

0.29-1.06 |

≤0.035 |

≤0.035 |

≥415 |

≥240 |

|

|

B |

≤0.35 |

≥0.10 |

0.29-1.06 |

≤0.035 |

≤0.035 |

≥485 |

≥275 |

|

ASTM A500 |

A |

≤0.26 |

- |

≤1.35 |

≤0.035 |

≤0.035 |

≥310 |

≥230 |

|

|

B |

≤0.30 |

- |

≤1.40 |

≤0.045 |

≤0.045 |

≥400 |

≥290 |

|

|

C |

≤0.23 |

- |

≤1.35 |

≤0.035 |

≤0.035 |

≥425 |

≥315 |

|

|

D |

≤0.27 |

- |

≤1.40 |

≤0.045 |

≤0.045 |

≥400 |

≥250 |

Your email address will not be published. Required fields are marked with *

Their products are of excellent quality and they offer generous discounts. This is their third cooperation