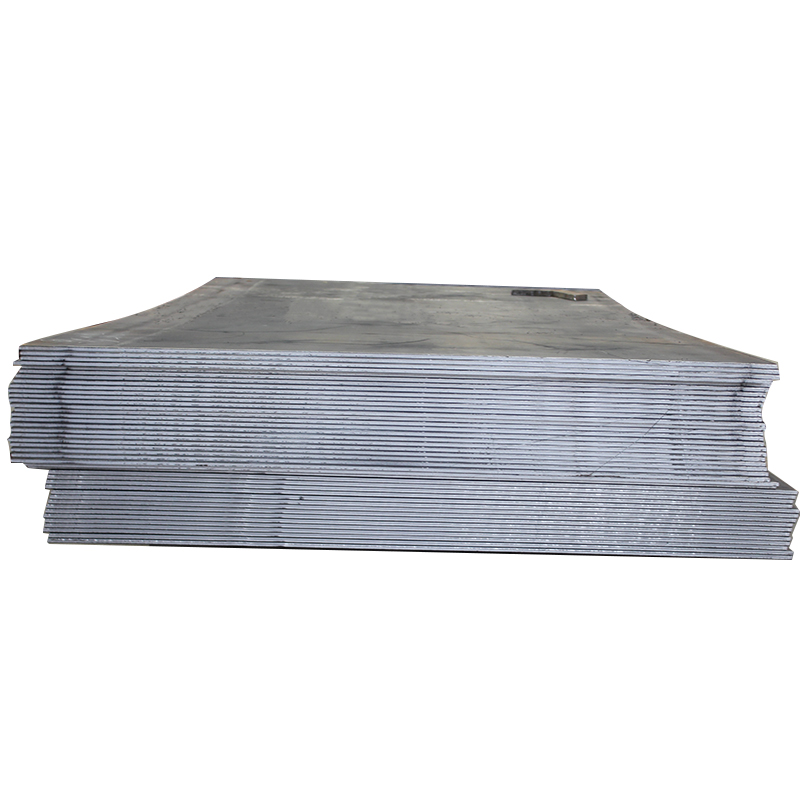

Cold Rolled Carbon Steel Sheet High Quality ST37

.Product Introduction

ST37 cold rolled carbon steel sheet is a widely used low-carbon structural steel product, renowned for its excellent cost-effectiveness, stable mechanical properties, and broad adaptability to processing. It is part of the German DIN 17100 standard (a classic European steel standard for structural steels) and has become a staple in industries such as machinery manufacturing, automotive, construction, and home appliances due to its "high quality" attributes—including precise dimensions, smooth surface, and reliable performance.

Advantages

|

Advantage Category |

Key Performance/Feature |

|

Superior Surface Quality |

Smooth, blemish-free finish (Ra ≤1.6 μm); no scale/pits; uniform appearance for coating/plating |

|

High Dimensional Precision |

Strict thickness tolerance (±0.02 mm for 0.5-3mm sheets); flat, warp-free shape |

|

Balanced Mechanical Properties |

Yield strength ≥370 N/mm², tensile strength 430-560 N/mm²; elongation ≥25% (good formability) |

|

Strong Process Adaptability |

Excellent weldability (no preheating needed for common methods); compatible with painting/galvanizing; easy cutting/machining |

|

Cost-Effectiveness |

Low raw material cost (no expensive alloys); mature production process; global supply |

|

Environmental Friendliness |

≥90% recyclability; lower energy consumption in smelting/rolling vs alloy steel |

Why Choose US

Sky Steel Construction Co., Ltd. is a large-scale modern steel complex integratingsintering, ironmaking, steelmaking, continuous casting, steel rolling, and metal productsproduction processes. The company has more than 300 employees and has advanced 12high frequency welding production lines. With more than 30 years of experience in steelproduction, it can provide a variety of solutions to customer satisfaction.

Our company mainly deals in high-quality and low-cost steel wire,Carbon steel pipe,carbon steel plate, profiles, galvanized products, wire, steel mesh, etc. We can customizevarious sizes, materials, standards, and painting according to customer needs. . Withadvanced production technology and strict testing technology, the company passed the1509001-2000 international quality system certification in 2007.

FAQ

FAQ

Q1: What’s the minimum order quantity (MOQ)?

A: Typically 5 ton; negotiable for bulk regular orders.

Q2: How long to get samples?

A: 3-5 working days after sample confirmation.

Q3: What packaging is used?

A: Standard seaworthy packaging (wooden pallets + moisture-proof film).

Measurement method: direct measurement with digital thickness gauge and at a distance of no less than 1 inch from the edge

|

Width |

Thickness, inches |

|||||

|

0.027 a 0.051 inclusive |

0.051 a 0.057 inclusive |

0.057 a 0.071 inclusive |

0071 a 0.098 inclusive |

0.098 a 0.18 exclusive |

0.18 a 0.23 exclusive |

|

|

20 - 40 inches inclusive |

0.008 |

0.008 |

0.009 |

0.010 |

0.010 |

0.012 |

|

40 - 48 inches inclusive |

0.008 |

0.009 |

0.009 |

0.010 |

0.012 |

0.014 |

|

Width, mm |

Thickness, mm |

|||

|

Hasta 2 mm |

De 2 mm - 2.5 mm inclusive |

2.5 mm a 4.5 mm exclusive |

4.5 mm a 6.0 mm exclusive |

|

|

1200 a 1500 mm inclusive |

0.26 |

0.26 |

0.30 |

0.38 |

|

Minimum thickness, mm |

Nominal thickness, mm |

Maximum thickness, mm |

|

1.47 |

1.59 |

1.70 |

|

1.47 |

1.59 |

1.70 |

|

1.47 |

1.59 |

1.70 |

|

1.47 |

1.59 |

1.70 |

|

1.47 |

1.59 |

1.70 |

|

1.89 |

2.00 |

2.11 |

|

2.25 |

2.38 |

2.51 |

|

2.25 |

2.38 |

2.51 |

|

2.25 |

2.38 |

2.51 |

|

3.02 |

3.18 |

3.33 |

|

3.02 |

3.18 |

3.33 |

|

4.58 |

4.76 |

4.94 |

|

4.64 |

4.76 |

4.89 |

|

4.61 |

4.76 |

4.91 |

|

4.58 |

4.76 |

4.94 |

|

4.56 |

4.76 |

4.97 |

|

4.56 |

4.76 |

4.97 |

|

1.87 |

2.00 |

2.13 |

|

2.85 |

3.00 |

3.15 |

The width tolerance must be according to what is established in table 6 and 7 of the ASTM A568 standard (English System) depending on whether it is a mill edge or cut edge. There is no negative tolerance, only positive.

Width tolerance for mill Edge hot rolled Steel sheet

|

Width, inches |

Upper tolerance, no tolerance under specified width |

|

30 a 50 included |

+1 1/8” |

Width tolerance for cut Edge for hot rolled Steel sheet

|

Width, inches |

Upper tolerance, no tolerance under specified width |

|

30 to 48 inches (included) |

+3/16” |

Measurement method: direct measurement using a measuring tape

|

Hot rolled steel sheet |

Minimum width, mm |

Nominal width, mm |

Maximum width, mm |

|

3' X 6' X 1/16" |

914.40 |

914.40 |

919.16 |

|

3' X 6' X 3/16" |

914.40 |

914.40 |

919.16 |

|

3' X 7' X 1/16" |

914.40 |

914.40 |

919.16 |

|

3' X 8' X 1/16" |

914.40 |

914.40 |

919.16 |

|

3' X 8' X 3/16" |

914.40 |

914.40 |

919.16 |

|

4' X 8' X 1/16" |

1219.20 |

1219.20 |

1223.96 |

|

4' X 8' X 1/8" |

1219.20 |

1219.20 |

1223.96 |

|

4' X 8' X 3/16" |

1219.20 |

1219.20 |

1223.96 |

|

4' X 8' X 2.0mm |

1219.20 |

1219.20 |

1223.96 |

|

4' X 8' X 3.0mm |

1219.20 |

1219.20 |

1223.96 |

|

4' X 8' X 3/32" |

1219.20 |

1219.20 |

1223.96 |

|

4' X 10' X 1/16" |

1219.20 |

1219.20 |

1223.96 |

|

4' X 10' X 1/8" |

1219.20 |

1219.20 |

1223.96 |

|

4' X 10' X 3/16" |

1219.20 |

1219.20 |

1223.96 |

The length tolerance must be in accordance with what is established in table 8 of the ASTM A568 standard. There is no negative tolerance, only positive.

|

Length, inches |

Tolerance over, no tolerance under |

|

60 a 120 (included) (6, 7, 8, 9 y 10 pies) |

+ ¾” |

Measurement method: direct measurement using a measuring tape

|

Hot rolled steel sheet |

Minimum length, mm |

Nominal length, mm |

Maximum length, mm |

|

3' X 6' X 1/16" |

1828.80 |

1828.80 |

1847.85 |

|

3' X 6' X 3/16" |

1828.80 |

1828.80 |

1847.85 |

|

3' X 7' X 1/16" |

2133.60 |

2133.60 |

2152.65 |

|

3' X 8' X 1/16" |

2438.40 |

2438.40 |

2457.45 |

|

3' X 8' X 3/16" |

2438.40 |

2438.40 |

2457.45 |

|

4' X 8' X 1/16" |

2438.40 |

2438.40 |

2457.45 |

|

4' X 8' X 1/8" |

2438.40 |

2438.40 |

2457.45 |

|

4' X 8' X 3/16" |

2438.40 |

2438.40 |

2457.45 |

|

4' X 8' X 2.0mm |

2438.40 |

2438.40 |

2457.45 |

|

4' X 8' X 3.0mm |

2438.40 |

2438.40 |

2457.45 |

|

4' X 8' X 3/32" |

2438.40 |

2438.40 |

2457.45 |

|

4' X 10' X 1/16" |

3048.00 |

3048.00 |

3067.05 |

|

4' X 10' X 1/8" |

3048.00 |

3048.00 |

3067.05 |

|

4' X 10' X 3/16" |

3048.00 |

3048.00 |

3067.05 |

Maximum straightness should be according to table 10 of ASTM A568 Standard.

|

Length, feet |

Tolerance |

|

4 a 6 (included) |

3/16” |

|

6 a 8 (included) |

¼” |

|

8 a 10 (included) |

5/16” |

Method of measurement: According to ASTM A1030/A1030M Standard: Practice for Measuring Flatness Characteristics of Steel Sheet Products

|

Thickness, inches |

Width, inches |

Tolerance of flatness |

|||

|

Minumum yield strength, ksi |

|||||

|

Less than 45 |

45 to 55 |

55 to 80 |

80 to 100 |

||

|

0.057 a 0.18 exclusive (1/16, 1/8, 3/32) |

12 a 60 incl. |

1 ½ |

2 ¼ |

2 ½ |

2 ¾ |

|

60 a 72 incl. (6 feet) |

2 ¼ |

3 3/8” |

3 ½” |

3 ¾” |

|

|

> 72 incl. (7, 8 y 10 feet) |

3 |

4 ½ |

4 ¾ |

5 |

|

|

0.18 a 0.23 exclusive (3/16”) |

12 a 60 incl. |

1 ½ |

2 ¼ |

2 ¼ |

2 ¾ |

|

60 a 72 incl. (6 feet) |

2 ¼ |

3 3/8 |

3 3/8 |

3 ¾ |

|

|

>72 (7, 8 y 10 pies) |

3 |

4 ½ |

4 ½ |

5 |

|

Out of square

The out-of-square tolerance must be according to what is indicated in table 11 of the ASTM A568 standard.Out of square is the greatest deviation of the end of the edge from a straight line at right angles to one side touching the corner. It is also obtained by measuring the difference of diagonals. The out of square is half of this difference:The maximum out of square should be 1/16” per 6 inches width, that means, 1/8” / feet of width.

Measurement method: Direct measurement with tape measure

|

Width, feet |

Out of square, inches |

|

3 |

0.375 |

|

4 |

0.5 |

Chemical Composition

According to ASTM A36 Standard

|

Element |

Maximum concentration (w/w) |

|

C |

0.26 |

|

Mn |

N/A |

|

P |

0.04 |

|

S |

0.05 |

|

Si, max |

0.40 |

Mechanical characteristicas

The sheet must meet the mechanical requirements of grade 36 as indicated in the following table:

|

Characteristic |

Specification |

|

Yield strength, psi [MPa] |

36000 [250] |

|

Tensile strength, psi [MPa] |

58000 – 80000 [400 – 550] |

|

Elongation in 8 inches, % |

20% |

Your email address will not be published. Required fields are marked with *

Their products are of excellent quality and they offer generous discounts. This is their third cooperation