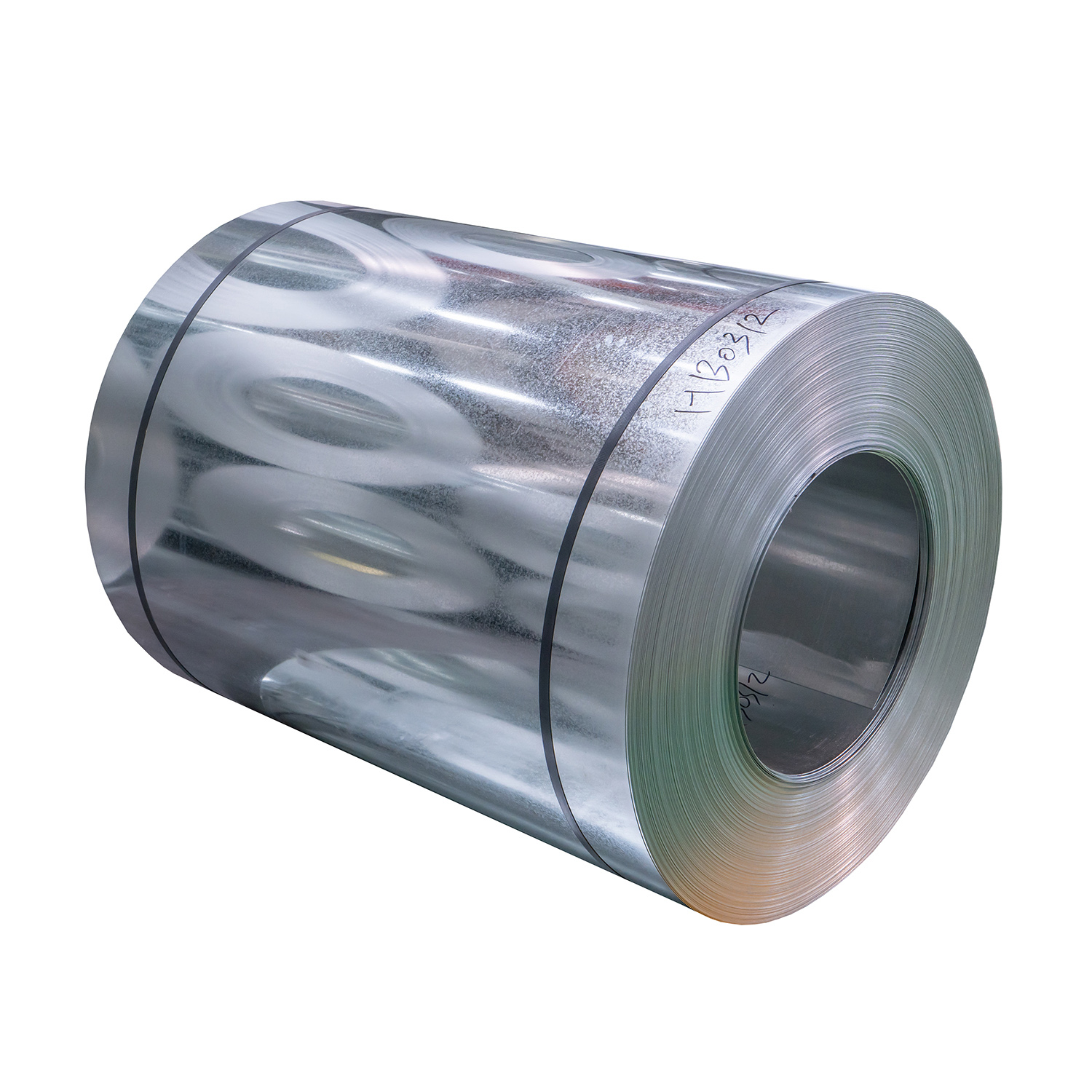

Hot Rolled Galvanized Carbon Steel Coils Best Price

1.Product Introduction

Our Hot Rolled Galvanized Carbon Steel Coils combine the strength of hot-rolled carbon steel with the corrosion resistance of zinc coating, making them a cost-effective and durable solution for diverse industrial applications. Crafted from high-quality carbon steel (conforming to standards like ASTM A36, S235JR, or Q235), the coils undergo a hot-dip galvanizing process—where the steel surface is fully immersed in molten zinc—forming a tight, adherent zinc layer (typically 60-275 g/m², customizable by requirement).

2.Why Choose Us?

✅ High-Strength Materials: Meet various load-bearing requirements.

✅ Customizable Solutions: Adjustable dimensions, materials, and surface treatments.

✅ Fast Delivery: Ample stock available, supporting small trial orders.

3.Simplified Zinc Choice Comparison Table

|

Zinc Coating Type |

Zinc Content/Weight |

|

Hot-Dip Galvanizing (HDG) |

60–275 g/m² (per side); 85–390 μm |

|

Electro-Galvanizing (EG) |

5–50 g/m² (per side); 7–70 μm |

|

Zinc-Nickel Alloy |

8–20 g/m² (total); 10–15% Ni |

|

Zinc-Rich Paint (ZRP) |

60–90% Zn in film; 50–200 μm |

|

Galvalume (Zn-Al Alloy) |

55% Al, 43.4% Zn; 100–200 g/m² |

4.FAQ

Q1: Can the zinc coating thickness be adjusted, and how does it impact performance?

A: Yes—we offer coating thickness from 60g/m² (light duty) to 275g/m² (heavy duty). Thicker coatings boost corrosion resistance (ideal for outdoor/coastal use), while thinner ones suit indoor

Q2: How long is the lead time for an order, and what’s the minimum order quantity (MOQ)?

A: Standard coils (common specs) have a 7-10 day lead time; custom specs take 12-15 days. MOQ is 1 coil (1-3 tons) for trial orders, with flexible terms for long-term partners.

Q3: Are the coils suitable for welding and painting?

A: Yes. The galvanized surface is weldable (use zinc-compatible welding rods to avoid porosity) and paintable (light sanding or primer ensures good paint adhesion) for further customization.

TYPSA allowed weights, diameters, widths and ovality

|

TYPSA |

||

|

Aspect |

HOT SHEET AND COLD SHEET |

|

|

Maximum |

Minimum |

|

|

Weight (kg) |

12,000 |

8,000 |

|

Width (mm) |

1219 |

1000 |

|

External diameter (mm) |

Do not exceed the specified weight |

No specification |

|

Internal diameter (mm) |

780 |

507 |

|

Ovality (mm) |

No specification |

No specification |

TUBAC permitted weights, diameters, widths and ovality (information for supplier use)

|

TUBAC |

||

|

Aspect |

SLITTER # 3 (LAMINA CALIENTE) |

|

|

Maximum |

Minimum |

|

|

Thickness |

8 |

0.9 |

|

Weight (Kg) |

22,000 |

11,000 |

|

Widht (mm) |

1500 |

914 |

|

External diameter (mm) |

2,200 |

No specification |

|

Internal diameter (mm) |

762 |

520 |

|

Ovality (mm) |

25 |

25 |

TUBAC permitted weights, diameters, widths and ovality(information for internal use)

|

Aspect |

BONAK |

|

|

|

Maximum |

Minimum |

|

Thickness |

8 |

0.7 |

|

Weight (Kg) |

22,000 |

11,000 |

|

Width (mm) |

1800 |

500 |

|

External diameter (mm) |

2200 |

1500 |

|

Internal diameter (mm) |

860 |

508 |

|

Ovality (mm) |

25 |

25 |

Chemical composition and mechanical properties of hot rolled sheet Grade D (Grade A)

|

Elemento (%) |

JIS G3132, grado SPHT-1 |

ASTM A1011 - CS TipoA |

|

C (máx) |

0.1 |

0.1 |

|

Mn (máx) |

0.5 |

0.6 |

|

P (máx) |

0.04 |

0.03 |

|

S (máx) |

0.04 |

0.035 |

|

Cu (máx) |

- |

0.2 |

|

Si (máx) |

** 0.03 |

** 0.03 |

|

Tensile strength (min) MPa |

270 min |

- |

|

Yield Strength (min) MPa |

- |

205 - 340 |

|

Elongation (%) |

37 |

25 min |

Chemical composition and mechanical properties of hot rolled sheet Grade B

|

Elemento (%) |

JIS G3101, grado SS400 |

ASTMA1011 - grado 36 |

|

C (máx) |

- |

0.25 |

|

Mn (máx) |

- |

1.35 |

|

P (máx) |

0.05 |

0.035 |

|

S (máx) |

0.05 |

0.04 |

|

Cu (máx) |

- |

0.2 |

|

Si (máx) |

** 0.03 |

** 0.03 |

|

Tensile strength (min) MPa |

400 - 510 |

400 - 550 |

|

Yield strength (min) MPa |

245 |

250 |

|

Elongation (%) |

21 |

21 |

Chemical composition and mechanical properties of Grade C hot rolled sheet

|

Elemento (%) |

ASTMA572, grado 50 |

ASTMA1011, grado 50 |

|

C (máx) |

0.23 |

0.25 |

|

Mn (máx) |

1.35 |

1.35 |

|

P (máx) |

0.03 |

0.035 |

|

S (máx) |

0.03 |

0.04 |

|

Cu (máx) |

- |

0.2 |

|

Si (máx) |

** 0.03 |

** 0.03 |

|

Resistencia a la tensión (min) MPa |

450 |

450 |

|

Límite de fluencia (min) MPa |

345 |

340 |

|

Elongación (%) |

21 |

17 |

Your email address will not be published. Required fields are marked with *

Their products are of excellent quality and they offer generous discounts. This is their third cooperation