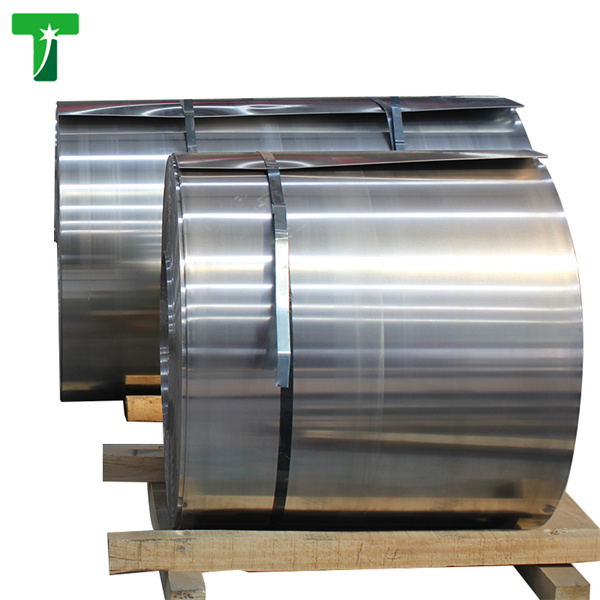

Manufacturers GI Cold Rolled Galvanized Carbon Steel Coil

1. Product Introduction

GI (Galvanized Iron) Cold Rolled Galvanized Carbon Steel Coil is a high-performance metal product made by applying a zinc coating to cold rolled carbon steel coils via hot-dip galvanizing (HDG) or electro-galvanizing processes. It combines the precision of cold rolled steel (smooth surface, tight dimensional tolerance) with the strong corrosion resistance of zinc, making it a staple in industries requiring durability and aesthetics.

2. Key Features

|

Feature Category |

Specific Performance |

|

Excellent Rust Prevention |

Zinc coating acts as a sacrificial barrier; service life 5-10x longer than uncoated steel |

|

Smooth, Uniform Surface |

Flat and consistent surface finish |

|

Good Formability |

Can be bent, stamped, or cut into complex parts without cracking |

|

Cost-Effectiveness |

Balances high performance (corrosion resistance, precision) and production cost |

3. About us

Sky Steel Construction Co., Ltd. is a large-scale modern steel complex integratingsintering, ironmaking, steelmaking, continuous casting, steel rolling, and metal productsproduction processes. The company has more than 300 employees and has advanced 12high frequency welding production lines. With more than 30 years of experience in steelproduction, it can provide a variety of solutions to customer satisfaction.

Our company mainly deals in high-quality and low-cost steel wire,Carbon steel pipe,carbon steel plate, profiles, galvanized products, wire, steel mesh, etc. We can customizevarious sizes, materials, standards, and painting according to customer needs. . Withadvanced production technology and strict testing technology, the company passed the1509001-2000 international quality system certification in 2007.

5.Our factory

6. FAQ

Q1: What’s the common zinc coating thickness?

A: 30-275 g/m²; 60-120 g/m² for general use.

Q2: How long does it resist rust outdoors?

A: 5-10 years (varies by coating thickness and environment).

Q3: Can it be welded?

A: Yes, but need to protect weld seams from rust after welding.

Q4: Is sample available?

A: Free small samples; freight collect.

Q5: What’s the MOQ for coils?

A: Typically 10 tons; negotiable for regular orders.

|

TYPSA |

||

|

Aspect |

LAMINA FRIA |

|

|

Minimum |

Maximum |

|

|

Weight (Kg) |

8,000 |

12,000 |

|

Width (mm) |

1000 |

1219 |

|

External diameter (mm) |

There is no specification |

Do not exceed the specified weight |

|

Internal diameter (mm) |

507 |

780 |

|

Ovality (mm) |

There is no specification |

There is no specification |

TUBAC permitted weights, diameters, widths and ovality(information for supplier use)

|

Aspect |

SLITTER # 4 |

|

|

Minimum |

Maximum |

|

|

Thickness |

0.6 |

2 |

|

Weight (Kg) |

6,000 |

16,000 |

|

Width (mm) |

904 |

1300 |

|

External diameter (mm) |

There is no specification |

1,800 |

|

Internal diameter (mm) |

484 |

762 |

|

Ovality (mm) |

25 |

25 |

TUBAC permitted weights, diameters, widths and ovality(information for internal use)

|

Aspect |

BONAK |

|

|

Minimum |

Maximum |

|

|

Thickness |

8 |

0.7 |

|

Weight (Kg) |

22,000 |

11,000 |

|

Width (mm) |

1800 |

500 |

|

External diameter (mm) |

2200 |

1500 |

|

Internal diameter (mm) |

860 |

508 |

|

Ovality (mm) |

25 |

25 |

Chemical composition of cold rolled sheet

|

Element (%) |

JIS G3141 SPCCT - SD |

ASTM A1008 CS-B |

|

C (max) |

0.15 |

0.02 - 0.15 |

|

Mn (max) |

1.00 |

0.60 |

|

P (max) |

0.100 |

0.025 |

|

S (max) |

0.035 |

0.035 |

Reference standard: JIS G3141, SPCCT-SD grade

Reference standard: ASTM A1008 CS-B

JIS G3141: Japanese Standard

SPCC: Indicates the grade for a commercial quality steel (Table No. 1 JIS G3141 Standard)

T: Consensus voltage resistance level (Table No. 5, note C, JIS G3141 Standard)

S: Standard hardness level (Table No. 2 JIS G3141 Standard)

D: Matte surface finish (Table No. 3 JIS G3141 Standard)

NOTE: Boron must be less than 0.0008% according to the Central American SAC Tariff system.

NOTE: If you wish to purchase cold rolled sheet with a different specification than the one in Table No. 1, you must do so using the FRM-0AI00003-15 Request for Exception to a Standard format, according to the standard EO-0AI00003-07 Non-compliance with standard.

5.2.Mechanical Specifications

Measurement method: Tensile test carried out on a universal mechanical testing machine according to ASTM A370 standard.

Mechanical properties of cold rolled sheet

|

Element (%) |

JIS G3141 SPCCT - SD |

ASTM A1008 CS-B |

|

Tensile strength (Mpa) min |

290 |

- |

|

Yield strength (Mpa) |

205 - 275 |

160 - 260 |

|

Elongation (%) min |

30 |

30 |

Reference standard: JIS G3141, SPCCT-SD grade

Reference standard: ASTM A1008 CS-B

JIS G3141: Japanese Standard

o SPCC: Indicates the grade for a commercial quality steel (Table No. 1 JIS G3141 Standard)

o T: Consensus voltage resistance level (Table No. 5, note C, JIS G3141 Standard)

Your email address will not be published. Required fields are marked with *

Their products are of excellent quality and they offer generous discounts. This is their third cooperation