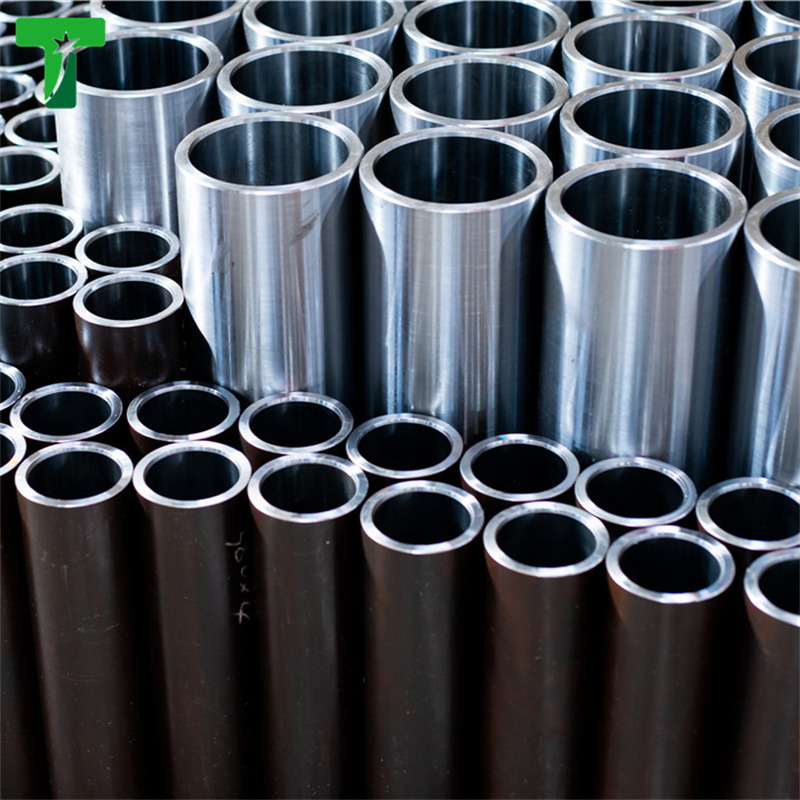

Electrical Conduit Galvanized Tubes UL Certified & Rust-Free Guarantee

What Are Galvanized Steel Pipes?

Galvanized steel pipes are carbon steel pipes coated with a protective zinc layer through galvanization, providing superior corrosion resistance and extended service life of 50+ years. Ideal for construction, plumbing, and industrial applications worldwide.

Product Grades & Standards

-

International Standards: ASTM A53 Gr.B, API 5L, BS 1387, EN 10219, JIS G3442

-

Certifications: ISO 9001, CE, SGS, BIS, SASO, GOST

-

Size Range: 1/2" to 8" OD, SCH 40 to SCH 160

-

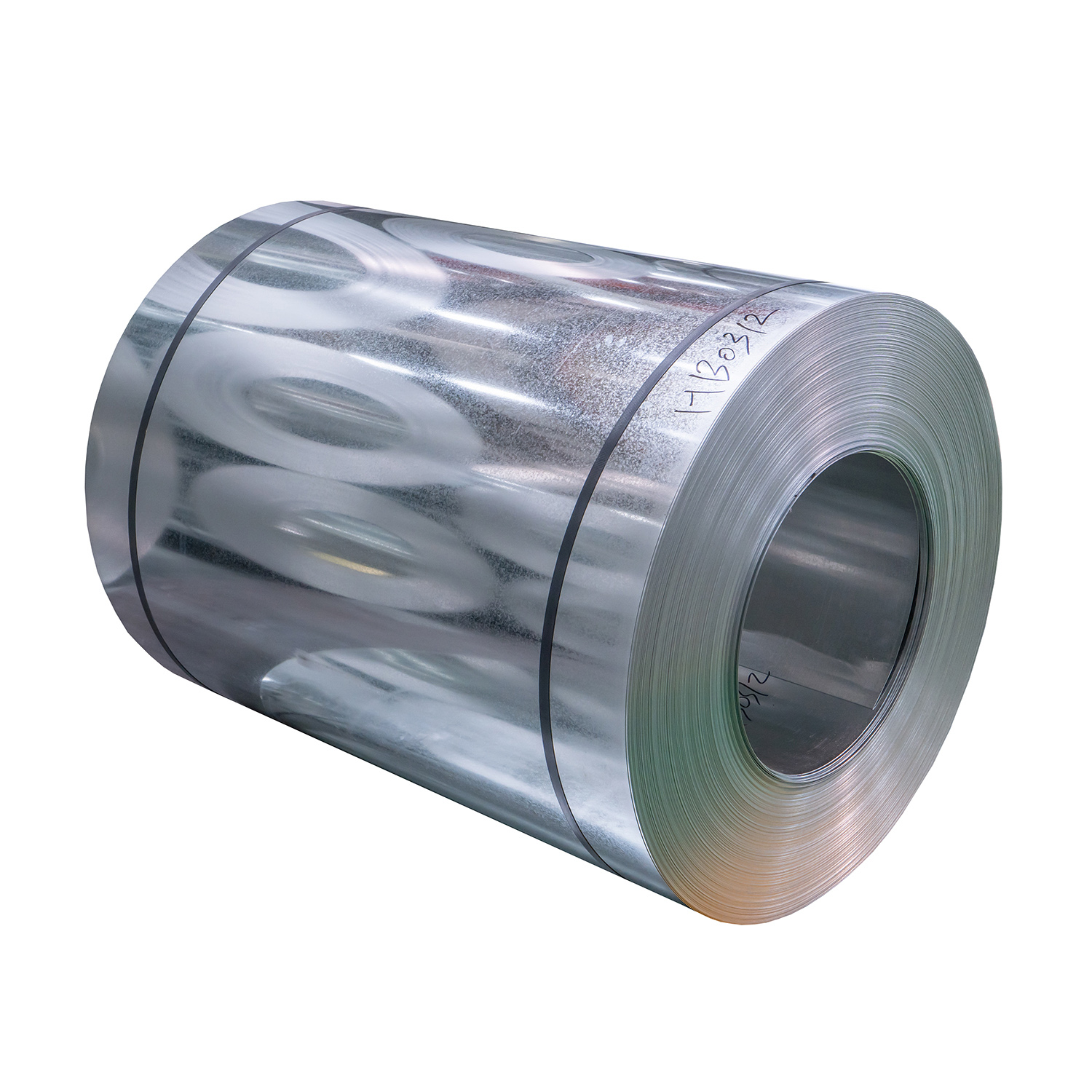

Coating Options: Hot-Dip Galvanized / Electro-Galvanized

Zinc Coating Specifications

Hot-Dip Galvanized Pipes:

-

Coating Process: Immersion in molten zinc (455°C)

-

Coating Thickness: 85-200μm (610-750 g/m²)

-

Coating Adhesion: Metallurgical bond

-

Service Life: 50+ years in harsh environments

-

Applications: Water systems, marine structures, outdoor construction

Cold Galvanized Pipes:

-

Coating Process: Electrolytic deposition

-

Coating Thickness: 5-25μm (10-50 g/m²)

-

Coating Adhesion: Mechanical bond

-

Service Life: 10-15 years in mild environments

-

Applications: Electrical conduits, indoor furniture, decorative uses

18 Years of Global Steel Expertise - Your Advantage

✅ Proven International Track Record

-

18 years specializing in steel exports to 60+ countries

-

Successful projects in USA, Europe, Middle East, and Asia

✅ Quality Assurance System

-

Triple-stage quality inspection process

-

Full material traceability from raw material to finished product

-

Compliance with international standards and certifications

✅ Global Logistics Expertise

-

Efficient shipping to major ports worldwide

-

Expert handling of customs documentation and clearance

-

Real-time shipment tracking available

✅ Competitive Manufacturing Advantage

-

State-of-the-art production facilities

-

Factory-direct pricing with 30% cost savings

-

Custom solutions for unique project requirements

✅ 24/7 Technical Support

-

Multi-lingual engineering team

-

Free technical consultation services

-

Fast response within 2 hours

Frequently Asked Questions

Q1: How do you ensure coating consistency in different climate conditions?

A: Our automated production line maintains precise temperature and timing controls, ensuring uniform coating thickness and adhesion regardless of destination climate.

Q2: What is your maximum production capacity for urgent projects?

A: We can produce 8,000+ tons monthly with consistent quality, and offer expedited production for urgent orders without compromising quality.

Q3: Can you provide country-specific certification packages?

A: Yes! With 18 years of export experience, we provide complete certification packages including CO, COC, Mill Test Certificates, and country-specific approvals.

What Are Galvanized Steel Pipes?

International Standards: ASTM A53 Gr.B, API 5L, BS 1387, EN 10219, JIS G3442

Certifications: ISO 9001, CE, SGS, BIS, SASO, GOST

Size Range: 1/2" to 8" OD, SCH 40 to SCH 160

Coating Options: Hot-Dip Galvanized / Electro-Galvanized

Coating Process: Immersion in molten zinc (455°C)

Coating Thickness: 85-200μm (610-750 g/m²)

Coating Adhesion: Metallurgical bond

Service Life: 50+ years in harsh environments

Applications: Water systems, marine structures, outdoor construction

Coating Process: Electrolytic deposition

Coating Thickness: 5-25μm (10-50 g/m²)

Coating Adhesion: Mechanical bond

Service Life: 10-15 years in mild environments

Applications: Electrical conduits, indoor furniture, decorative uses

18 years specializing in steel exports to 60+ countries

Successful projects in USA, Europe, Middle East, and Asia

Triple-stage quality inspection process

Full material traceability from raw material to finished product

Compliance with international standards and certifications

Efficient shipping to major ports worldwide

Expert handling of customs documentation and clearance

Real-time shipment tracking available

State-of-the-art production facilities

Factory-direct pricing with 30% cost savings

Custom solutions for unique project requirements

Multi-lingual engineering team

Free technical consultation services

Fast response within 2 hours

A: Our automated production line maintains precise temperature and timing controls, ensuring uniform coating thickness and adhesion regardless of destination climate.

A: We can produce 8,000+ tons monthly with consistent quality, and offer expedited production for urgent orders without compromising quality.

A: Yes! With 18 years of export experience, we provide complete certification packages including CO, COC, Mill Test Certificates, and country-specific approvals.

Product Description

|

Product |

A53 Galvanized Pipe |

|

Standard |

ASTM A53 / ASME SA53 |

|

Material |

Carbon Steel |

|

Grades |

A53 Grade A, A53 Grade B |

|

Outer Diameter (OD) |

1/2” – 48” (21.3mm – 1219mm) |

|

Wall Thickness |

SCH10, SCH20, SCH40, SCH80, SCH160, XXS |

|

Length |

6m, 12m, or custom lengths |

|

Pipe End |

Plain End, Beveled End, Threaded & Coupled |

|

Zinc Coating |

40g/m² – 600g/m² |

|

Technique |

ERW (Electric Resistance Welded), Seamless, LSAW, SSAW |

|

Surface Treatment |

Hot – Dipped Galvanized, Pre – Galvanized, Black Coated |

|

Connection Type |

Welding, Threaded, Flanged |

|

Protection |

Plastic Caps, Bundled with Steel Strips, Waterproof Wrapping |

|

Certification |

ISO, SGS, BV, CE |

|

Stock Availability |

10,000+ Tons Per Month |

Chemical Composition of ASTM A53

|

Element |

Grade A (%) |

Grade B (%) |

|

Carbon (C) |

≤ 0.25 |

≤ 0.30 |

|

Manganese (Mn) |

≤ 0.95 |

≤ 1.20 |

|

Phosphorus (P) |

≤ 0.05 |

≤ 0.05 |

|

Sulfur (S) |

≤ 0.045 |

≤ 0.045 |

|

Copper (Cu) |

≤ 0.40 |

≤ 0.40 |

|

Nickel (Ni) |

≤ 0.40 |

≤ 0.40 |

|

Chromium (Cr) |

≤ 0.40 |

≤ 0.40 |

|

Molybdenum (Mo) |

≤ 0.15 |

≤ 0.15 |

Mechanical Properties of ASTM A53

|

Property |

Grade A |

Grade B |

|

Yield Strength (MPa) |

≥ 205 MPa |

≥ 240 MPa |

|

Tensile Strength (MPa) |

330 – 380 MPa |

415 – 550 MPa |

|

Elongation (%) |

≥ 20% |

≥ 15% |

|

Hardness (Brinell) |

≤ 90 HB |

≤ 100 HB |

Galvanized Coating Options

|

Coating Type |

Zinc Thickness |

Application |

|

Pre – Galvanized |

40 – 150 g/m² |

Indoor & low – corrosion environments |

|

Hot – Dipped Galvanized |

200 – 600 g/m² |

Heavy – duty industrial & outdoor use |

Equivalent Grades

|

Standard |

Equivalent Grade |

|

ASTM |

A53 |

|

EN |

S235, S275 |

|

JIS |

STK400, STK500 |

|

GB |

Q195, Q235, Q345 |

Your email address will not be published. Required fields are marked with *

Their products are of excellent quality and they offer generous discounts. This is their third cooperation