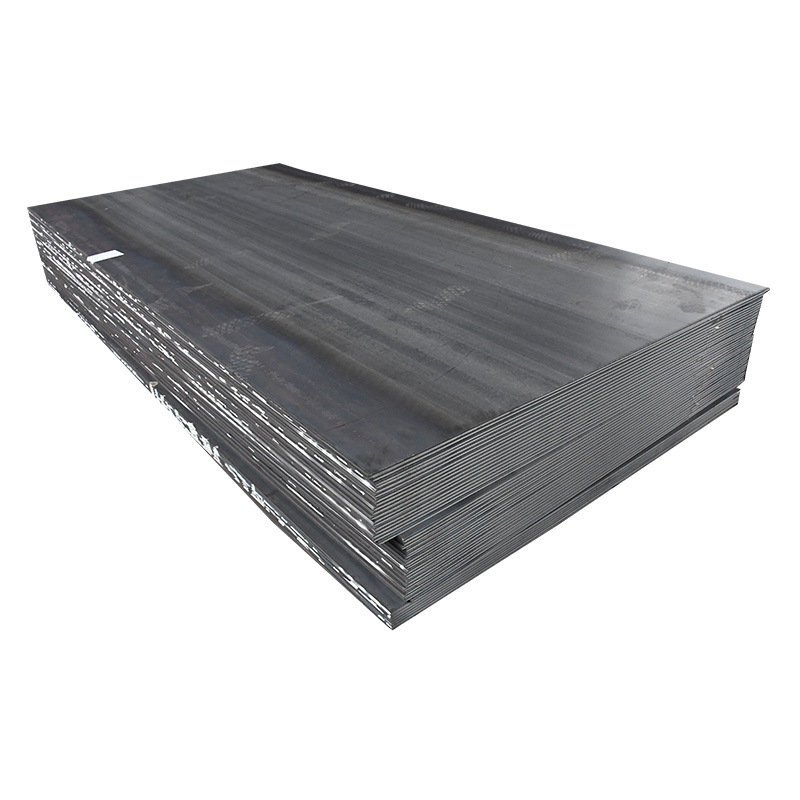

Carbon Steel Hot Rolled Plate Black S235JR SS400 Mild Steel Plate

Product Introduction

Hot rolled steel plate is produced by rolling steel ingots or continuous casting billets through a rolling mill at high temperatures. This manufacturing process endows the steel plate with several distinct characteristics. It exhibits high plasticity, making it highly suitable for forming operations. Additionally, it has good weldability, facilitating its use in various welded structures. However, its relatively low hardness is a characteristic that needs to be considered in specific applications.

Applications

|

Application Type |

Typical Uses |

|

Structural Steel |

Steel structures, bridges, ships, vehicles |

|

Weathering Steel |

Container manufacturing, special vehicles, building structures |

|

Automotive Structural Steel |

Automotive components (e.g., FRAME, WHEEL) |

|

Special Hot Rolled Steel |

Mechanical parts (after heat treatment) |

|

Cold Rolled Base Plate |

Production of cold-rolled products (CR, GI, color-coated sheets) |

|

Steel Plate for Steel Pipe |

High-pressure gas vessels (≤500L; for LPG, acetylene, etc.) |

|

Steel Plate for High-Pressure Vessels |

High-pressure gas vessels (with specialized needs) |

|

Stainless Steel Plate |

Food industry, surgical equipment, aerospace, petroleum/chemical industries |

Why Choose our Product?

1.Global Standard Compliance

Adhere to GB/T 709-2019, JIS G3131, ASTM A1018/A1018M, EN10025; every batch passes multi-inspections (thickness, mechanics, corrosion) for stable quality.

2.Scenario-Tailored Performance

Full product range (structural/weathering/automotive/stainless steel, etc.) optimized for needs:

Weathering steel (P/Cu added): anti-corrosion for outdoors;

Automotive steel: high-strength, good stamping/weldability;

Cold-rolled base plate: uniform thickness for downstream processing.

3.Reliable Supply

Advanced rolling/casting lines reduce defects; sufficient monthly output + flexible delivery avoid project delays.

FAQ

Q:What is hot rolled steel plate?

A:It’s a steel product made by rolling steel ingots or continuous casting billets at high temperatures (usually above 900°C).

Q:Does hot rolled steel plate have good weldability?

A:Yes, most hot rolled steel grades (e.g., structural steel) have good weldability, making them suitable for welded structures.

Q:What are the main uses of hot rolled steel plate?

A:Commonly used for steel structures, bridges, ships, automotive components, containers, and as raw material for cold-rolled products.

Measurement method: direct measurement with digital thickness gauge and at a distance of no less than 1 inch from the edge

|

Width |

Thickness, inches |

|||||

|

0.027 a 0.051 inclusive |

0.051 a 0.057 inclusive |

0.057 a 0.071 inclusive |

0071 a 0.098 inclusive |

0.098 a 0.18 exclusive |

0.18 a 0.23 exclusive |

|

|

20 - 40 inches inclusive |

0.008 |

0.008 |

0.009 |

0.010 |

0.010 |

0.012 |

|

40 - 48 inches inclusive |

0.008 |

0.009 |

0.009 |

0.010 |

0.012 |

0.014 |

|

Width, mm |

Thickness, mm |

|||

|

Hasta 2 mm |

De 2 mm - 2.5 mm inclusive |

2.5 mm a 4.5 mm exclusive |

4.5 mm a 6.0 mm exclusive |

|

|

1200 a 1500 mm inclusive |

0.26 |

0.26 |

0.30 |

0.38 |

|

Minimum thickness, mm |

Nominal thickness, mm |

Maximum thickness, mm |

|

1.47 |

1.59 |

1.70 |

|

1.47 |

1.59 |

1.70 |

|

1.47 |

1.59 |

1.70 |

|

1.47 |

1.59 |

1.70 |

|

1.47 |

1.59 |

1.70 |

|

1.89 |

2.00 |

2.11 |

|

2.25 |

2.38 |

2.51 |

|

2.25 |

2.38 |

2.51 |

|

2.25 |

2.38 |

2.51 |

|

3.02 |

3.18 |

3.33 |

|

3.02 |

3.18 |

3.33 |

|

4.58 |

4.76 |

4.94 |

|

4.64 |

4.76 |

4.89 |

|

4.61 |

4.76 |

4.91 |

|

4.58 |

4.76 |

4.94 |

|

4.56 |

4.76 |

4.97 |

|

4.56 |

4.76 |

4.97 |

|

1.87 |

2.00 |

2.13 |

|

2.85 |

3.00 |

3.15 |

The width tolerance must be according to what is established in table 6 and 7 of the ASTM A568 standard (English System) depending on whether it is a mill edge or cut edge. There is no negative tolerance, only positive.

Width tolerance for mill Edge hot rolled Steel sheet

|

Width, inches |

Upper tolerance, no tolerance under specified width |

|

30 a 50 included |

+1 1/8” |

Width tolerance for cut Edge for hot rolled Steel sheet

|

Width, inches |

Upper tolerance, no tolerance under specified width |

|

30 to 48 inches (included) |

+3/16” |

Measurement method: direct measurement using a measuring tape

|

Hot rolled steel sheet |

Minimum width, mm |

Nominal width, mm |

Maximum width, mm |

|

3' X 6' X 1/16" |

914.40 |

914.40 |

919.16 |

|

3' X 6' X 3/16" |

914.40 |

914.40 |

919.16 |

|

3' X 7' X 1/16" |

914.40 |

914.40 |

919.16 |

|

3' X 8' X 1/16" |

914.40 |

914.40 |

919.16 |

|

3' X 8' X 3/16" |

914.40 |

914.40 |

919.16 |

|

4' X 8' X 1/16" |

1219.20 |

1219.20 |

1223.96 |

|

4' X 8' X 1/8" |

1219.20 |

1219.20 |

1223.96 |

|

4' X 8' X 3/16" |

1219.20 |

1219.20 |

1223.96 |

|

4' X 8' X 2.0mm |

1219.20 |

1219.20 |

1223.96 |

|

4' X 8' X 3.0mm |

1219.20 |

1219.20 |

1223.96 |

|

4' X 8' X 3/32" |

1219.20 |

1219.20 |

1223.96 |

|

4' X 10' X 1/16" |

1219.20 |

1219.20 |

1223.96 |

|

4' X 10' X 1/8" |

1219.20 |

1219.20 |

1223.96 |

|

4' X 10' X 3/16" |

1219.20 |

1219.20 |

1223.96 |

The length tolerance must be in accordance with what is established in table 8 of the ASTM A568 standard. There is no negative tolerance, only positive.

|

Length, inches |

Tolerance over, no tolerance under |

|

60 a 120 (included) (6, 7, 8, 9 y 10 pies) |

+ ¾” |

Measurement method: direct measurement using a measuring tape

|

Hot rolled steel sheet |

Minimum length, mm |

Nominal length, mm |

Maximum length, mm |

|

3' X 6' X 1/16" |

1828.80 |

1828.80 |

1847.85 |

|

3' X 6' X 3/16" |

1828.80 |

1828.80 |

1847.85 |

|

3' X 7' X 1/16" |

2133.60 |

2133.60 |

2152.65 |

|

3' X 8' X 1/16" |

2438.40 |

2438.40 |

2457.45 |

|

3' X 8' X 3/16" |

2438.40 |

2438.40 |

2457.45 |

|

4' X 8' X 1/16" |

2438.40 |

2438.40 |

2457.45 |

|

4' X 8' X 1/8" |

2438.40 |

2438.40 |

2457.45 |

|

4' X 8' X 3/16" |

2438.40 |

2438.40 |

2457.45 |

|

4' X 8' X 2.0mm |

2438.40 |

2438.40 |

2457.45 |

|

4' X 8' X 3.0mm |

2438.40 |

2438.40 |

2457.45 |

|

4' X 8' X 3/32" |

2438.40 |

2438.40 |

2457.45 |

|

4' X 10' X 1/16" |

3048.00 |

3048.00 |

3067.05 |

|

4' X 10' X 1/8" |

3048.00 |

3048.00 |

3067.05 |

|

4' X 10' X 3/16" |

3048.00 |

3048.00 |

3067.05 |

Maximum straightness should be according to table 10 of ASTM A568 Standard.

|

Length, feet |

Tolerance |

|

4 a 6 (included) |

3/16” |

|

6 a 8 (included) |

¼” |

|

8 a 10 (included) |

5/16” |

Method of measurement: According to ASTM A1030/A1030M Standard: Practice for Measuring Flatness Characteristics of Steel Sheet Products

|

Thickness, inches |

Width, inches |

Tolerance of flatness |

|||

|

Minumum yield strength, ksi |

|||||

|

Less than 45 |

45 to 55 |

55 to 80 |

80 to 100 |

||

|

0.057 a 0.18 exclusive (1/16, 1/8, 3/32) |

12 a 60 incl. |

1 ½ |

2 ¼ |

2 ½ |

2 ¾ |

|

60 a 72 incl. (6 feet) |

2 ¼ |

3 3/8” |

3 ½” |

3 ¾” |

|

|

> 72 incl. (7, 8 y 10 feet) |

3 |

4 ½ |

4 ¾ |

5 |

|

|

0.18 a 0.23 exclusive (3/16”) |

12 a 60 incl. |

1 ½ |

2 ¼ |

2 ¼ |

2 ¾ |

|

60 a 72 incl. (6 feet) |

2 ¼ |

3 3/8 |

3 3/8 |

3 ¾ |

|

|

>72 (7, 8 y 10 pies) |

3 |

4 ½ |

4 ½ |

5 |

|

Out of square

The out-of-square tolerance must be according to what is indicated in table 11 of the ASTM A568 standard.Out of square is the greatest deviation of the end of the edge from a straight line at right angles to one side touching the corner. It is also obtained by measuring the difference of diagonals. The out of square is half of this difference:The maximum out of square should be 1/16” per 6 inches width, that means, 1/8” / feet of width.

Measurement method: Direct measurement with tape measure

|

Width, feet |

Out of square, inches |

|

3 |

0.375 |

|

4 |

0.5 |

Chemical Composition

According to ASTM A36 Standard

|

Element |

Maximum concentration (w/w) |

|

C |

0.26 |

|

Mn |

N/A |

|

P |

0.04 |

|

S |

0.05 |

|

Si, max |

0.40 |

Mechanical characteristicas

The sheet must meet the mechanical requirements of grade 36 as indicated in the following table:

|

Characteristic |

Specification |

|

Yield strength, psi [MPa] |

36000 [250] |

|

Tensile strength, psi [MPa] |

58000 – 80000 [400 – 550] |

|

Elongation in 8 inches, % |

20% |

Your email address will not be published. Required fields are marked with *

Their products are of excellent quality and they offer generous discounts. This is their third cooperation