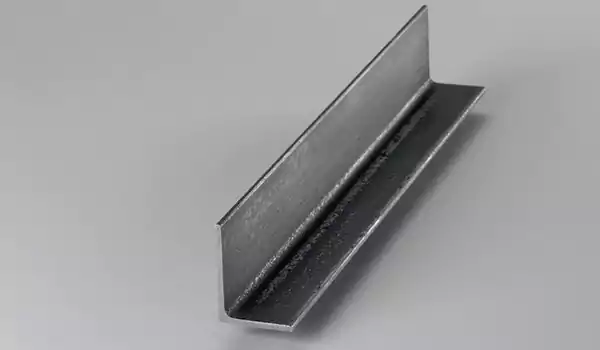

A-36 S355JR Angle Steel

SPECIFICATIONS: ASTM A36 Steel, Hot Rolled, Carbon Steel FINISH: Blue / Gray, Slightly grainy MECHANICAL PROPERTIES Yield Point: 36,000 psi Tensile Strength: 58-80,000 psi Elongation = 23% in 2" Elasticity = 29,000 psi Brinell Hardness = 119-158 Machinability Rate = 72% CHEMICAL PROPERTIES 98% Iron, .25-.29% Carbon, .20% Copper, .04% max Silicon, .60 - .90% Manganese, .04% Phosphorous, .05% Sulfur TOLERANCES AVAILABLE LENGTHS 2' 4' 6' 8' 10' 20' Custom Lengths

Dimensional Tolerances for Equal Angles

|

Dimension Category |

Symbol |

Tolerance (A36, ASTM A6/A6M-24) |

Tolerance (S355JR, EN 10056-1:2020) |

Measurement Method |

|

Leg Length |

L |

- L ≤ 75mm: ±1.0mm |

- L ≤ 100mm: ±1.0mm |

Measured from outer edge to heel (inside corner) at both ends; average of 4 readings |

|

Leg Thickness |

t |

- t ≤ 10mm: ±10% of nominal t |

- t ≤ 10mm: ±0.8mm |

Measured at 1/4, 1/2, and 3/4 of leg length with a micrometer (±0.01mm accuracy) |

|

Root Radius |

r |

+0.8mm / -0mm (all sizes) |

- L ≤ 100mm: 6mm ±1mm |

Check with radius gauge gauge at heel (inside corner) where legs intersect |

|

Toe Radius |

rₜ |

+0.5mm / -0mm (all sizes) |

2mm ±0.5mm (all sizes) |

Measure at outer leg corners (toes) with radius gauge |

|

Length of Angle |

Lₜ |

- Random: +150mm / -0mm |

- Random: +100mm / -0mm |

Steel tape (±1mm/m accuracy) from end to end; exclude zinc coating for galvanized angles |

|

Leg Squareness |

- |

90° ±1° (L ≤100mm); 90° ±1.5° (L >100mm) |

90° ±1° (all sizes) |

Protractor (±0.1° accuracy) at both ends; average of 2 readings |

Dimensional Tolerances for Unequal Angles

|

Dimension Category |

Symbol |

Tolerance (A36, ASTM A6/A6M-24) |

Tolerance (S355JR, EN 10056-1:2020) |

Measurement Notes |

|

Longer Leg Length |

L₁ |

Same as equal angles (based on L₁) |

Same as equal angles (based on L₁) |

Primary load-bearing leg; stricter tolerance for structural stability |

|

Shorter Leg Length |

L₂ |

- L₂ ≤ 75mm: ±0.8mm |

- L₂ ≤ 100mm: ±0.8mm |

Secondary leg; tolerance scaled to leg length |

|

Leg Thickness |

t |

Same as equal angles (unified thickness for both legs) |

Same as equal angles (unified thickness for both legs) |

Thickness consistent across both legs; measured at mid-length of each leg |

|

Root Radius |

r |

+0.8mm / -0mm (all sizes) |

Based on longer leg: same as equal angles |

Larger radius for larger longer legs to reduce stress concentration |

Straightness and Flatness Tolerances

|

Tolerance Type |

A36 (ASTM A6/A6M-24) |

S355JR (EN 10056-1:2020) |

Testing Method |

|

Lengthwise Straightness |

≤1.5mm/m (total: ≤1.5×Lₜ mm, Lₜ = length in meters) |

≤1.0mm/m (total: ≤1.0×Lₜ mm) |

Place on flat surface; measure max gap with feeler gauge (0.01-1.0mm range) |

|

Leg Flatness |

≤0.6mm per 100mm leg length (max 3mm) |

≤0.5mm per 100mm leg length (max 2mm) |

Straightedge (grade 1) along leg; measure gap at mid-length |

|

Twist |

≤1.0mm per 300mm length (max 5mm for Lₜ ≤6m) |

≤0.8mm per 300mm length (max 4mm for Lₜ ≤6m) |

Lay on flat surface; measure height difference of one leg at 300mm intervals |

|

End Squareness |

≤1.5mm (L ≤100mm); ≤2.0mm (L >100mm) |

≤1.0mm (L ≤100mm); ≤1.5mm (L >100mm) |

Square against end face; measure gap with feeler gauge |

Notes:

A36 (ASTM) and S355JR (EN) angle steels have similar dimensional tolerances but differ slightly in strictness—S355JR generally has tighter controls for flatness and straightness.

For galvanized angles, add 70-100μm (0.07-0.10mm) to outer dimensions when checking post-galvanization tolerances (per ASTM A123 or EN 10240).

Tolerances apply to hot-rolled angles in as-delivered condition. Cold-worked or machined angles require custom tolerance agreements.

Measurement temperature: 20℃±5℃ to avoid thermal expansion effects. For critical applications, verify with certified calibration tools.

Leg thickness is critical for load calculations—ensure measurements exclude edge burrs (≤0.5mm height, not counted in tolerance).

Chemical Composition of A36 and S355JR Angle Steel (Mass Fraction, ≤ %)

|

Element |

A36 (ASTM A36/A36M-24) |

S355JR (EN 10025-2:2019) |

Note on Role |

|

C (Carbon) |

≤ 0.25 |

≤ 0.20 |

Enhances strength; lower in S355JR for better weldability and toughness |

|

Si (Silicon) |

≤ 0.40 |

≤ 0.55 |

Deoxidizer; higher range in S355JR supports strength without brittleness |

|

Mn (Manganese) |

0.85–1.20 |

≤ 1.60 |

Improves tensile strength; S355JR allows higher content for superior strength |

|

P (Phosphorus) |

≤ 0.040 |

≤ 0.035 |

Strictly limited in both; lower in S355JR to prevent cold brittleness |

|

S (Sulfur) |

≤ 0.050 |

≤ 0.035 |

Minimized to reduce weld defects; tighter control in S355JR |

|

Cu (Copper) |

≥ 0.20 (optional) |

≤ 0.30 |

Optional in A36 for corrosion resistance; trace in S355JR has no adverse effect |

|

Cr (Chromium) |

≤ 0.30 (max, if present) |

≤ 0.30 |

Trace element; no impact on mechanical properties in either grade |

|

Ni (Nickel) |

≤ 0.30 (max, if present) |

≤ 0.30 |

Enhances toughness; controlled to balance performance and cost |

|

Mo (Molybdenum) |

— (not specified) |

≤ 0.10 |

Trace in S355JR; improves hardenability slightly |

|

V (Vanadium) |

— (not specified) |

≤ 0.05 |

Optional in S355JR; refines grain structure for better strength-ductility balance |

|

N (Nitrogen) |

≤ 0.015 |

≤ 0.012 |

Stabilized in S355JR (with Ti/Nb) to prevent aging brittleness |

|

Ti (Titanium) |

— (not specified) |

≤ 0.10 |

Grain refiner in S355JR; improves toughness |

|

Nb (Niobium) |

— (not specified) |

≤ 0.05 |

Works with Ti in S355JR to stabilize nitrogen and refine grains |

Mechanical Properties of A36 and S355JR Angle Steel

|

Property |

A36 (ASTM A36/A36M-24) |

S355JR (EN 10025-2:2019) |

Test Standard |

Application Impact |

|

Yield Strength (Rp0.2, ≥) |

250 MPa |

355 MPa |

ASTM E8/E8M (A36); EN ISO 6892-1 (S355JR) |

S355JR offers 42% higher yield strength, enabling lighter structural designs |

|

Tensile Strength (Rm) |

400–550 MPa |

470–630 MPa |

Same as above |

S355JR has a higher tensile range, suitable for heavy load-bearing applications |

|

Elongation After Fracture (A, ≥) |

20% (t ≤ 19mm) |

22% (t ≤ 16mm) |

Same as above |

S355JR maintains good ductility despite higher strength |

|

Impact Absorption Energy (KV2) |

≥ 27 J (room temp, optional) |

≥ 34 J (20℃) |

ASTM A370 (A36); EN ISO 148-1 (S355JR) |

S355JR requires mandatory impact toughness, critical for structural safety |

|

Hardness (Brinell, HB) |

≤ 170 HB |

≤ 230 HB |

ASTM E10; EN ISO 6506-1 |

Higher hardness in S355JR aligns with its greater strength |

|

Weldability |

Excellent (no preheat for t ≤ 25mm) |

Excellent (preheat for t > 25mm) |

AWS D1.1 (A36); EN 1011-2 (S355JR) |

Both are weldable; S355JR may need mild preheat for thick sections to prevent cracking |

|

Cold Formability |

Good |

Good (with proper technique) |

ASTM E290; EN ISO 7438 |

S355JR requires controlled forming to avoid cracking due to higher strength |

Notes:

All values comply with the latest standards (ASTM A36/A36M-24 and EN 10025-2:2019, as of 2024). For angles with thickness (t) > 19mm, properties may have slight adjustments—refer to standard supplements.

A36 is a carbon structural steel, while S355JR is a European standard structural steel with higher strength and stricter impurity controls.

For corrosive environments, both grades can be hot-dip galvanized (zinc coating 70–100μm). Galvanizing does not alter base metal chemistry or mechanical properties.

Mechanical tests are performed on transverse specimens (relative to rolling direction) to reflect real-world structural behavior under load.

S355JR’s lower carbon and sulfur contents make it more suitable for welding in critical structures (e.g., bridges, high-rise buildings) compared to A36.

Your email address will not be published. Required fields are marked with *

Their products are of excellent quality and they offer generous discounts. This is their third cooperation