W Beam American Wide Flange Beams

Parameter of Wide Flange Beams

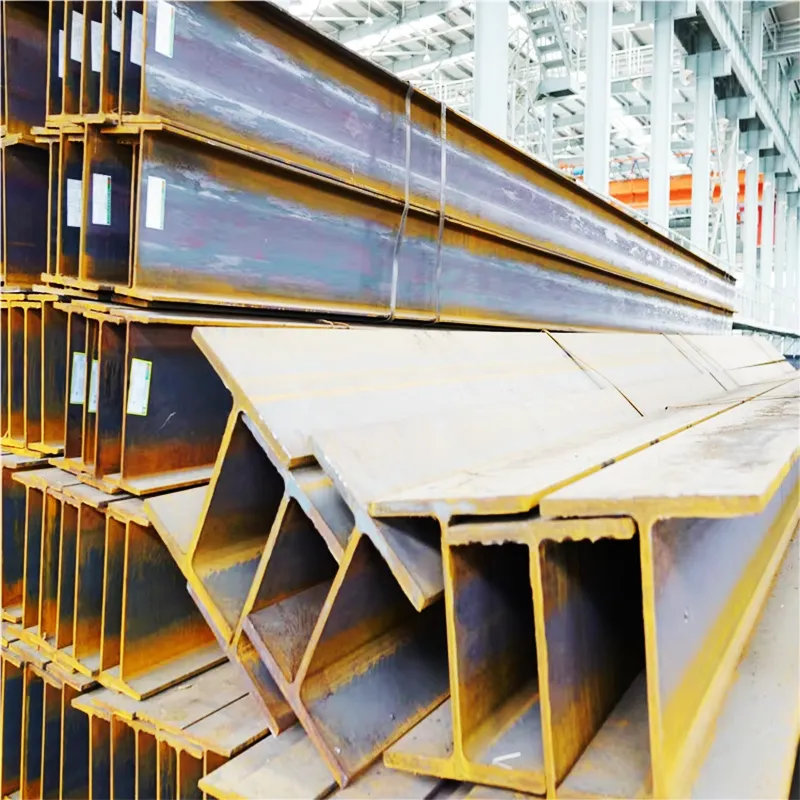

Wide flange beams have attracted much attention in the engineering field for their excellent structural performance and wide applicability. As a key structural steel, it plays an indispensable role in various construction and infrastructure projects.

WF Beam, named after its unique cross-sectional shape resembling the letters "H" or "W". It consists of wide flanges located at the top and bottom, as well as a web plate vertically connecting the flanges. This structure endows the wide flange beam with excellent mechanical properties. The increase in the width of the wing edge enables the steel beam to more effectively resist deformation and improve its bending resistance.

|

Standard

|

American Standard |

| Material | Q235B Q355B SS400 ASTM A36 S235 S355 |

|

Size

|

Web Width (H): 100-900mm

Flange Width (B): 100-300mm Web Thickness (t1): 5-30mm Flange Thickness (t2): 5-30m |

|

Length

|

6m / 9m / 12m or customized length as per client request

|

|

Application

|

Construction structure / Building construction

|

Common Industry Applications

Builders use W-beams throughout the construction industry to build a wide array of different residential, commercial, and municipal structures. Some of the most common uses include:

-

Mainly used for frame structures in commercial buildings, industrial plants, residential buildings, etc

-

Widely used in the construction of highway bridges and railway bridges, as the main structural material for main beams and bridge piers

-

Used to build large-scale equipment detection and provide a stable support platform for it

-

In tower structures such as communication towers and transmission towers, w-beams serve as the main supporting components to ensure stability

Steel W-beam Size

|

Designation Imperial (in x lb/ft) |

Depth h (in) |

Width w (in) |

Web Thickness tw (in) |

Flange Thickness tf (in) |

Sectional Area (in2) |

Weight (lbf/ft) |

|---|---|---|---|---|---|---|

| W 27 x 178 | 27.8 | 14.09 | 0.725 | 1.190 | 52.3 | 178 |

| W 27 x 161 | 27.6 | 14.02 | 0.660 | 1.080 | 47.4 | 161 |

| W 27 x 146 | 27.4 | 14 | 0.605 | 0.975 | 42.9 | 146 |

| W 27 x 114 | 27.3 | 10.07 | 0.570 | 0.930 | 33.5 | 114 |

| W 27 x 102 | 27.1 | 10.02 | 0.515 | 0.830 | 30.0 | 102 |

| W 27 x 94 | 26.9 | 10 | 0.490 | 0.745 | 27.7 | 94 |

| W 27 x 84 | 26.7 | 9.96 | 0.460 | 0.640 | 24.8 | 84 |

| W 24 x 162 | 25 | 13 | 0.705 | 1.220 | 47.7 | 162 |

| W 24 x 146 | 24.7 | 12.9 | 0.650 | 1.090 | 43.0 | 146 |

| W 24 x 131 | 24.5 | 12.9 | 0.605 | 0.960 | 38.5 | 131 |

| W 24 x 117 | 24.3 | 12.8 | 0.55 | 0.850 | 34.4 | 117 |

| W 24 x 104 | 24.1 | 12.75 | 0.500 | 0.750 | 30.6 | 104 |

| W 24 x 94 | 24.1 | 9.07 | 0.515 | 0.875 | 27.7 | 94 |

| W 24 x 84 | 24.1 | 9.02 | 0.470 | 0.770 | 24.7 | 84 |

| W 24 x 76 | 23.9 | 9 | 0.440 | 0.680 | 22.4 | 76 |

| W 24 x 68 | 23.7 | 8.97 | 0.415 | 0.585 | 20.1 | 68 |

| W 24 x 62 | 23.7 | 7.04 | 0.430 | 0.590 | 18.2 | 62 |

| W 24 x 55 | 23.6 | 7.01 | 0.395 | 0.505 | 16.2 | 55 |

| W 21 x 147 | 22.1 | 12.51 | 0.720 | 1.150 | 43.2 | 147 |

| W 21 x 132 | 21.8 | 12.44 | 0.650 | 1.035 | 38.8 | 132 |

| W 21 x 122 | 21.7 | 12.39 | 0.600 | 0.960 | 35.9 | 122 |

| W 21 x 111 | 21.5 | 12.34 | 0.550 | 0.875 | 32.7 | 111 |

| W 21 x 101 | 21.4 | 12.29 | 0.500 | 0.800 | 29.8 | 101 |

| W 21 x 93 | 21.6 | 8.42 | 0.580 | 0.930 | 27.3 | 93 |

| W 21 x 83 | 21.4 | 8.36 | 0.515 | 0.835 | 24.3 | 83 |

| W 21 x 73 | 21.2 | 8.3 | 0.455 | 0.740 | 21.5 | 73 |

| W 21 x 68 | 21.1 | 8.27 | 0.430 | 0.685 | 20.0 | 68 |

| W 21 x 62 | 21 | 8.24 | 0.400 | 0.615 | 18.3 | 62 |

| W 21 x 57 | 21.1 | 6.56 | 0.405 | 0.650 | 16.7 | 57 |

| W 21 x 50 | 20.8 | 6.53 | 0.380 | 0.535 | 14.7 | 50 |

| W 21 x 44 | 20.7 | 6.5 | 0.350 | 0.450 | 13.0 | 44 |

| W 18 x 119 | 19 | 11.27 | 0.655 | 1.060 | 35.1 | 119 |

| W 18 x 106 | 18.7 | 11.2 | 0.590 | 0.940 | 31.1 | 106 |

| W 18 x 97 | 18.6 | 11.15 | 0.535 | 0.870 | 28.5 | 97 |

| W 18 x 86 | 18.4 | 11.09 | 0.480 | 0.770 | 25.3 | 86 |

| W 18 x 76 | 18.2 | 11.04 | 0.425 | 0.680 | 22.3 | 76 |

| W 18 x 71 | 18.5 | 7.64 | 0.495 | 0.810 | 20.8 | 71 |

| W 18 x 65 | 18.4 | 7.59 | 0.450 | 0.750 | 19.1 | 65 |

| W 18 x 60 | 18.2 | 7.56 | 0.415 | 0.695 | 17.6 | 60 |

| W 18 x 55 | 18.1 | 7.53 | 0.390 | 0.630 | 16.2 | 55 |

| W 18 x 50 | 18 | 7.5 | 0.355 | 0.570 | 14.7 | 50 |

| W 18 x 46 | 18.1 | 6.06 | 0.360 | 0.605 | 13.5 | 46 |

| W 18 x 40 | 17.9 | 6.02 | 0.315 | 0.525 | 11.8 | 40 |

| W 18 x 35 | 17.7 | 6 | 0.300 | 0.425 | 10.3 | 35 |

| W 16 x 100 | 16.97 | 10.425 | 0.585 | 0.985 | 29.4 | 100 |

| W 16 x 89 | 16.75 | 10.365 | 0.525 | 0.875 | 26.2 | 89 |

| W 16 x 77 | 16.52 | 10.295 | 0.455 | 0.760 | 22.6 | 77 |

| W 16 x 67 | 16.33 | 10.235 | 0.395 | 0.665 | 19.7 | 67 |

| W 16 x 57 | 16.43 | 7.120 | 0.430 | 0.715 | 16.8 | 57 |

| W 16 x 50 | 16.26 | 7.070 | 0.380 | 0.630 | 14.7 | 50 |

| W 16 x 45 | 16.13 | 7.035 | 0.345 | 0.565 | 13.3 | 45 |

| W 16 x 40 | 16.01 | 6.995 | 0.305 | 0.505 | 11.8 | 40 |

| W 16 x 36 | 15.86 | 6.985 | 0.295 | 0.430 | 10.6 | 36 |

| W 16 x 31 | 15.88 | 5.525 | 0.275 | 0.440 | 9.12 | 31 |

| W 16 x 26 | 15.69 | 5.5 | 0.250 | 0.345 | 7.68 | 26 |

| W 14 x 132 | 14.66 | 14.725 | 0.645 | 1.030 | 38.8 | 132 |

| W 14 x 120 | 14.48 | 14.670 | 0.590 | 0.940 | 35.3 | 120 |

| W 14 x 109 | 14.32 | 14.605 | 0.525 | 0.860 | 32 | 109 |

| W 14 x 99 | 14.16 | 14.565 | 0.485 | 0.780 | 29.1 | 99 |

| W 14 x 90 | 14.02 | 14.520 | 0.440 | 0.710 | 26.5 | 90 |

| W 14 x 82 | 14.31 | 10.130 | 0.510 | 0.855 | 24.1 | 82 |

| W 14 x 74 | 14.17 | 10.070 | 0.450 | 0.785 | 21.8 | 74 |

| W 14 x 68 | 14.04 | 10.035 | 0.415 | 0.720 | 20.0 | 68 |

| W 14 x 61 | 13.89 | 9.995 | 0.375 | 0.645 | 17.9 | 61 |

| W 14 x 53 | 13.92 | 8.060 | 0.370 | 0.660 | 15.6 | 53 |

| W 14 x 48 | 13.79 | 8.030 | 0.340 | 0.595 | 14.1 | 48 |

| W 14 x 43 | 13.66 | 7.995 | 0.305 | 0.530 | 12.6 | 43 |

| W 14 x 38 | 14.10 | 6.770 | 0.310 | 0.515 | 11.2 | 38 |

| W 14 x 34 | 13.98 | 6.745 | 0.285 | 0.455 | 10.0 | 34 |

| W 14 x 30 | 13.84 | 6.730 | 0.270 | 0.385 | 8.85 | 30 |

| W 14 x 26 | 13.91 | 5.025 | 0.255 | 0.420 | 7.69 | 26 |

| W 14 x 22 | 13.74 | 5 | 0.230 | 0.335 | 6.49 | 22 |

|

|

|

|

|

|

|

|

| W 12 x 136 | 13.41 | 12.4 | 0.79 | 1.250 | 39.9 | 136 |

| W 12 x 120 | 13.12 | 12.32 | 0.71 | 1.105 | 35.3 | 120 |

| W 12 x 106 | 12.89 | 12.22 | 0.61 | 0.990 | 31.2 | 106 |

| W 12 x 96 | 12.71 | 12.16 | 0.55 | 0.900 | 28.2 | 96 |

| W 12 x 87 | 12.53 | 12.125 | 0.515 | 0.810 | 25.6 | 87 |

| W 12 x 79 | 12.38 | 12.08 | 0.47 | 0.735 | 23.2 | 79 |

| W 12 x 72 | 12.25 | 12.04 | 0.43 | 0.670 | 21.1 | 72 |

| W 12 x 65 | 12.12 | 12 | 0.39 | 0.605 | 19.1 | 65 |

| W 12 x 58 | 12.19 | 10.01 | 0.36 | 0.640 | 17.0 | 58 |

| W 12 x 53 | 12.06 | 9.995 | 0.345 | 0.575 | 15.6 | 53 |

| W 12 x 50 | 12.19 | 8.08 | 0.37 | 0.640 | 14.7 | 50 |

| W 12 x 45 | 12.06 | 8.045 | 0.335 | 0.575 | 13.2 | 45 |

| W 12 x 40 | 11.94 | 8.005 | 0.295 | 0.515 | 11.8 | 40 |

| W 12 x 35 | 12.50 | 6.56 | 0.3 | 0.520 | 10.3 | 35 |

| W 12 x 30 | 12.34 | 6.52 | 0.26 | 0.440 | 8.8 | 30 |

| W 12 x 26 | 12.22 | 6.490 | 0.23 | 0.380 | 7.7 | 26 |

| W 12 x 22 | 12.31 | 4.03 | 0.26 | 0.425 | 6.5 | 22 |

| W 12 x 19 | 12.16 | 4.005 | 0.235 | 0.350 | 5.6 | 19 |

| W 12 x 16 | 11.99 | 3.990 | 0.22 | 0.265 | 4.7 | 16 |

| W 12 x 14 | 11.91 | 3.970 | 0.2 | 0.225 | 4.2 | 14 |

| W 10 x 112 | 11.36 | 10.415 | 0.755 | 1.250 | 32.9 | 112 |

| W 10 x 100 | 11.1 | 10.340 | 0.680 | 1.1120 | 29.4 | 100 |

| W 10 x 88 | 10.84 | 10.265 | 0.605 | 0.990 | 25.9 | 88 |

| W 10 x 77 | 10.60 | 10.190 | 0.530 | 0.870 | 22.6 | 77 |

| W 10 x 68 | 10.40 | 10.130 | 0.470 | 0.770 | 20.0 | 68 |

| W 10 x 60 | 10.22 | 10.080 | 0.420 | 0.680 | 17.6 | 60 |

| W 10 x 54 | 10.09 | 10.030 | 0.370 | 0.615 | 15.8 | 54 |

| W 10 x 49 | 9.98 | 10 | 0.340 | 0.560 | 14.4 | 49 |

| W 10 x 45 | 10.10 | 8.020 | 0.350 | 0.620 | 13.3 | 45 |

| W 10 x 39 | 9.92 | 7.985 | 0.315 | 0.530 | 11.5 | 39 |

| W 10 x 33 | 9.73 | 7.960 | 0.290 | 0.435 | 9.71 | 33 |

| W 10 x 30 | 10.47 | 5.81 | 0.3 | 0.510 | 8.84 | 30 |

| W 10 x 26 | 10.33 | 5.770 | 0.26 | 0.440 | 7.6 | 26 |

| W 10 x 22 | 10.17 | 5.750 | 0.240 | 0.360 | 6.5 | 22 |

| W 10 x 19 | 10.24 | 4.020 | 0.250 | 0.395 | 5.6 | 19 |

| W 10 x 17 | 10.11 | 4.010 | 0.240 | 0.330 | 5 | 17 |

| W 10 x 15 | 9.99 | 4 | 0.230 | 0.270 | 4.4 | 15 |

| W 10 x 12 | 9.87 | 3.960 | 0.190 | 0.210 | 3.5 | 12 |

| W 8 x 67 | 9.00 | 8.280 | 0.570 | 0.935 | 19.7 | 67 |

| W 8 x 58 | 8.75 | 8.220 | 0.510 | 0.810 | 17.1 | 58 |

| W 8 x 48 | 8.5 | 8.110 | 0.400 | 0.685 | 14.1 | 48 |

| W 8 x 40 | 8.25 | 8.070 | 0.360 | 0.560 | 11.7 | 40 |

| W 8 x 35 | 8.12 | 8.020 | 0.310 | 0.495 | 10.3 | 35 |

| W 8 x 31 | 8.00 | 7.995 | 0.285 | 0.435 | 9.1 | 31 |

| W 8 x 28 | 8.06 | 6.535 | 0.285 | 0.465 | 8.3 | 28 |

| W 8 x 24 | 7.93 | 6.495 | 0.245 | 0.400 | 7.1 | 24 |

| W 8 x 21 | 8.28 | 5.270 | 0.250 | 0.400 | 6.2 | 21 |

| W 8 x 18 | 8.14 | 5.250 | 0.230 | 0.330 | 5.3 | 18 |

| W 8 x 15 | 8.11 | 4.015 | 0.245 | 0.315 | 4.4 | 15 |

| W 8 x 13 | 7.99 | 4 | 0.230 | 0.255 | 3.8 | 13 |

| W 8 x 10 | 7.89 | 3.940 | 0.170 | 0.205 | 2.9 | 10 |

| W 6 x 25 | 6.38 | 6.080 | 0.320 | 0.455 | 7.3 | 25 |

| W 6 x 20 | 6.20 | 6.020 | 0.260 | 0.365 | 5.9 | 20 |

| W 6 x 16 | 6.28 | 4.030 | 0.260 | 0.405 | 4.7 | 16 |

| W 6 x 15 | 5.99 | 5.990 | 0.230 | 0.260 | 4.4 | 15 |

| W 6 x 12 | 6.03 | 4 | 0.230 | 0.280 | 3.6 | 12 |

| W 6 x 9 | 5.90 | 3.940 | 0.170 | 0.215 | 2.7 | 9 |

| W 5 x 19 | 5.15 | 5.030 | 0.270 | 0.430 | 5.5 | 19 |

| W 5 x 16 | 5.01 | 5 | 0.240 | 0.360 | 4.7 | 16 |

| W 4 x 13 | 4.16 | 4.060 | 0.280 | 0.345 | 3.8 | 13 |

Features of Wide Flange Beams

-

High quality material selection: Mainly using carbon steel and low-alloy steel. Carbon steel has good comprehensive performance and high cost-effectiveness, suitable for general construction; Low alloy steel has high strength, toughness, and corrosion resistance, making it suitable for large-scale projects with strict requirements.

-

Excellent mechanical performance: High strength bearing capacity, good stability, impact resistance, and seismic performance.

-

Advanced hot rolling technology: improves production efficiency, enhances product mechanical properties and surface quality.

-

We can provide a wide range of standard specifications and also offer customized services.

Your email address will not be published. Required fields are marked with *

Their products are of excellent quality and they offer generous discounts. This is their third cooperation