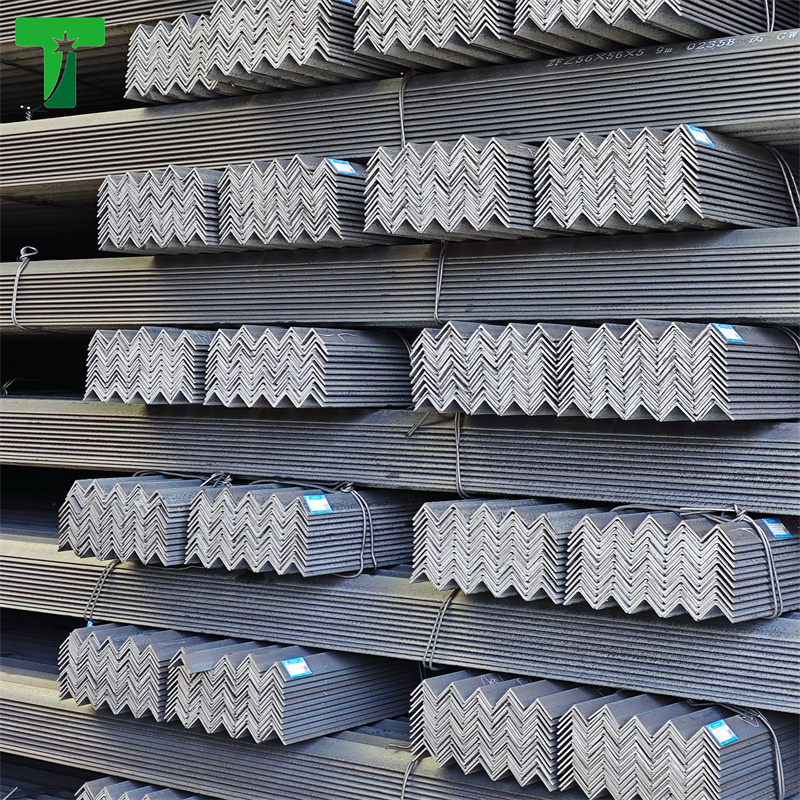

S355J2 S235 S275J2 Mild Steel Angle Iron Gi Steel Angle Bar

Angle Steel (Angle Bar) Introduction

Angle steel is a long, straight steel member with an L-shaped cross-section, formed by hot rolling steel billets or welding two flat bars at a 90° angle (welded angle steel is less common for structural use). Its two perpendicular segments are called "legs," and the junction of the legs is known as the "fillet" (a rounded or sharp corner, depending on the production process).

Key Structural Classifications

The primary distinction between angle steel variants lies in the length of their legs:

Equal-Leg Angle Steel: Both legs have the same length (e.g., 50×50×5, where the first two numbers denote leg length, and the third denotes leg thickness). This type is widely used for symmetric load-bearing and framing.

Unequal-Leg Angle Steel: The two legs have different lengths (e.g., 75×50×6, where the first number is the longer leg, the second the shorter leg, and the third the thickness). It is optimized for asymmetric load scenarios, such as connecting components of varying sizes.

Key Performance Characteristics

Excellent Load-Bearing & Rigidity: The L-shaped cross-section enhances torsional and bending resistance, allowing it to withstand both axial loads (compression/tension) and lateral forces. The fillet junction distributes stress evenly between the two legs, preventing localized deformation.

Superior Structural Connectivity: The perpendicular legs provide flat, accessible surfaces for welding, bolting, or riveting to other structural elements (e.g., beams, plates, or other angle steels). This makes it ideal for forming frames, trusses, and bracing systems.

High Material Efficiency: The compact L-shape concentrates material where stress is highest, avoiding waste while maintaining performance. Compared to solid bars of equivalent strength, it reduces overall structural weight.

Versatile Fabrication: Easy to cut, drill, bend, and weld using standard tools. It can be customized into complex shapes (e.g., triangular frames) for specialized applications without compromising strength.

Cost-Effectiveness: As a standardized hot-rolled product, it benefits from mass production, mature technology, and low processing costs—making it more economical than custom-shaped structural steel.

L Shapes (Equal leg)

|

|

Length of leg (mm) |

Thickness (mm) |

|||||||||

|

Producto |

Calidad |

Mín 团 |

Nom |

Máx |

Mín |

Nom |

Máx |

|

|

|

|

|

PERFIL ANGULAR 3/4"X1/8"X6M |

Legítimo |

18.26 |

19.05 |

19.84 |

2.97 |

3.18 |

3.38 |

|

|

|

|

|

PERFIL ANGULAR 3/4"X1/8X6MC |

Comercial |

18.26 |

19.05 |

19.84 |

2.00 |

2.20 |

2.40 |

|

|

|

|

|

PERFIL ANGULAR 3/4"X1/8X6M R |

Milimétrico |

18.26 |

19.05 |

19.84 |

2.60 |

2.70 |

2.80 |

|

|

|

|

|

PERFIL ANGULAR 1"X1/4"X6M |

Legítimo |

24.61 |

25.40 |

26.19 |

6.10 |

6.35 |

6.60 |

|

|

|

|

|

PERFIL ANGULAR 1"X1/8"X6M |

Legítimo |

24.61 |

25.40 |

26.19 |

2.97 |

3.18 |

3.38 |

|

|

|

|

|

PERFIL ANGULAR 1"X3/16"X6M |

Legítimo |

24.61 |

25.40 |

26.19 |

4.56 |

4.76 |

4.97 |

|

|

|

|

|

PERFIL ANGULAR 1"X1/8"X6MC |

Comercial |

24.61 |

25.40 |

26.19 |

2.10 |

2.20 |

2.30 |

|

|

|

|

|

PERFIL ANGULAR 1"X1/8X6M R |

Milimétrico |

24.61 |

25.40 |

26.19 |

2.60 |

2.70 |

2.80 |

|

|

|

|

|

PERFIL ANGULAR 1 1/4"X1/8X6MC |

Comercial |

30.51 |

31.75 |

32.89 |

2.10 |

2.20 |

2.30 |

|

|

|

|

|

PERFIL ANGULAR 1 1/4"X1/8X6M R |

Milimétrico |

30.51 |

31.75 |

32.89 |

2.60 |

2.70 |

2.80 |

|

|

|

|

|

PERFIL ANGULAR 1 1/4"X1/8"X6M |

Legítimo |

30.56 |

31.75 |

32.94 |

2.92 |

3.18 |

3.43 |

|

|

|

|

|

PERFIL ANGULAR 1 1/4"X3/16"X6M |

Legítimo |

30.56 |

31.75 |

32.94 |

4.51 |

4.76 |

5.02 |

|

|

|

|

|

PERFIL ANGULAR 1 1/4"X1/4"X6M |

Legítimo |

30.56 |

31.75 |

32.94 |

6.10 |

6.35 |

6.60 |

|

|

|

|

|

PERFIL ANGULAR 1 1/2"X1/8"X6M |

Legítimo |

36.91 |

38.10 |

39.29 |

2.92 |

3.18 |

3.43 |

|

|

|

|

|

PERFIL ANGULAR 1 1/2"X3/16"X6M |

Legítimo |

36.91 |

38.10 |

39.29 |

4.51 |

4.76 |

5.02 |

|

|

|

|

|

PERFIL ANGULAR 1 1/2"X1/4"X6M |

Legítimo |

36.91 |

38.10 |

39.29 |

6.10 |

6.35 |

6.60 |

|

|

|

|

|

PERFIL ANGULAR 1 1/2"X1/8X6M R |

Milimétrico |

36.91 |

38.10 |

39.29 |

2.60 |

2.70 |

2.80 |

|

|

|

|

|

PERFIL ANGULAR 1 1/2"X1/8X6MC |

Comercial |

36.91 |

38.10 |

39.29 |

2.10 |

2.20 |

2.30 |

|

|

|

|

|

PERFIL ANGULAR 1 1/2"X3/16X6M R |

Milimétrico |

36.91 |

38.10 |

39.29 |

3.90 |

4.00 |

4.10 |

|

|

|

|

|

PERFIL ANGULAR 2"X1/8"X6M R |

Milimétrico |

49.00 |

50.80 |

51.60 |

2.60 |

2.70 |

2.80 |

|

|

|

|

|

PERFIL ANGULAR 2"X1/8"X6M |

Legítimo |

49.61 |

50.80 |

51.99 |

2.92 |

3.18 |

3.43 |

|

|

|

|

|

PERFIL ANGULAR 2"X3/16"X6M |

Legítimo |

49.61 |

50.80 |

51.99 |

4.51 |

4.76 |

5.02 |

|

|

|

|

|

PERFIL ANGULAR 2"X1/4"X6M |

Legítimo |

49.61 |

50.80 |

51.99 |

6.10 |

6.35 |

6.60 |

|

|

|

|

|

PERFIL ANGULAR 2"X3/8"X6M |

Legítimo |

49.61 |

50.80 |

51.99 |

9.27 |

9.53 |

9.78 |

|

|

|

|

|

PERFIL ANGULAR 2 1/2"X3/16"X6M |

Legítimo |

61.91 |

63.50 |

65.09 |

4.46 |

4.76 |

5.07 |

|

|

|

|

|

PERFIL ANGULAR 2 1/2"X1/4"X6M |

Legítimo |

61.91 |

63.50 |

65.09 |

5.97 |

6.35 |

6.73 |

|

|

|

|

|

PERFIL ANGULAR 2 1/2"X3/8"X6M |

Legítimo |

61.91 |

63.50 |

65.09 |

9.14 |

9.53 |

9.91 |

|

|

|

|

|

PERFIL ANGULAR 3"X3/16"X6M |

Legítimo |

73.82 |

76.20 |

79.38 |

4.4577 |

4.76 |

5.0673 |

|

|

|

|

|

PERFIL ANGULAR 3"X1/4"X6M |

Legítimo |

73.82 |

76.20 |

79.38 |

2.41935 |

6.35 |

6.731 |

|

|

|

|

|

PERFIL ANGULAR 3"X1/2"X6M |

Legítimo |

73.82 |

76.20 |

79.38 |

No esp. |

12.70 |

No esp. |

|

|

|

|

|

PERFIL ANGULAR 3"X3/8"X6M |

Legítimo |

73.82 |

76.20 |

79.38 |

No esp. |

9.53 |

No esp. |

|

|

|

|

|

PERFIL ANGULAR 4"X1/4"X6M |

Legítimo |

99.22 |

101.60 |

104.78 |

No esp. |

6.35 |

No esp. |

|

|

|

|

|

PERFIL ANGULAR 4"X3/8"X6M |

Legítimo |

99.22 |

101.60 |

104.78 |

No esp. |

9.53 |

No esp. |

|

|

|

|

|

PERFIL ANGULAR 4"X1/2"X6M |

Legítimo |

99.22 |

101.60 |

104.78 |

No esp. |

12.70 |

No esp. |

|

|

|

|

Measurement method: Trace reference material from end to end and measure between the reference material and the shape at its greatest distance.

|

Product |

Width |

Maximum straightness, mm |

|

|

L Shape |

< 3 inches |

25 mm |

|

|

≥3 inches |

12.5 mm |

|

|

|

Round bar |

|

25 mm |

|

|

Square bar |

|

25 mm |

|

|

Flat |

|

25 mm |

|

|

T Shape |

|

25 mm |

|

|

C Shape |

|

25 mm |

|

|

Yield point, psi (Autographic Diagram Method according to ASTM A370 standard) |

36,000 |

|

Tensile strength, psi |

58,000 - 80,000 |

|

Elongation in 8 in, % |

20 |

De acuerdo a lo establecido en la norma ASTM A36

|

Element |

Specification |

|

C |

0.26 |

|

Mn |

|

|

P |

0.04 |

|

S |

0.05 |

|

Si, máx |

0.40 |

According to ASTM A6 Standard, Structural products shall be free of injurious

defects and shall have a workmanlike finish.

Free of rust

Cut: straight cut

Tie with strapping or wire rod

Protected to prevent rust in transport

Quality certificate must include heat number, chemical composition, tensile test results

Your email address will not be published. Required fields are marked with *

Their products are of excellent quality and they offer generous discounts. This is their third cooperation