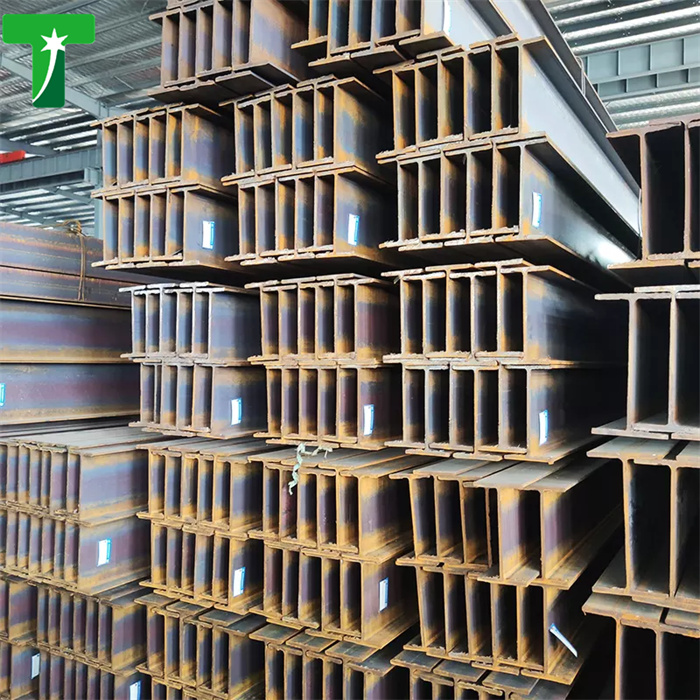

ASTM A36 H Beam Q345b Steel H-Beams S275jr S355jr A572 A992 Steel H Beam

1. Product Introduction

Our hot-rolled H-beams (also called wide flange beams) are premium structural steel sections designed for superior load-bearing capacity in construction and industrial applications. Manufactured to ASTM A36/A992, GB/T 11263, JIS G3192, and EN 10025 standards, these beams offer excellent strength-to-weight ratio and durability.

2.Specifications of H-beam steel

H-beam steel is available in a wide range of sizes and dimensions, allowing for flexibility in design and construction. The specific sizes and dimensions of H-beam steel can vary depending on regional standards and manufacturer specifications. However, here are some common H-beam steel sizes and dimensions:

Height (H): The height of an H-beam steel refers to the vertical distance between the top and bottom flanges. Millimeters (mm) or inches (in) are commonly used measurement units.

Flange Width (B): The flange width of an H-beam steel refers to the horizontal width of each flange. Millimeters (mm) or inches (in) are commonly used measurement units..

Web Thickness (t1): The web thickness of an H-beam steel refers to the thickness of the vertical web connecting the two flanges. Millimeters (mm) or inches (in) are commonly used measurement units.

Flange Thickness (t2): The flange thickness of an H-beam steel refers to the thickness of each flange. Millimeters (mm) or inches (in) are commonly used measurement units.

|

Product Name |

Steel H Beam, H Section Steel Beams, H Shape Steel Beam, Structural Steel H Beam, H Metal Beam |

|

Sizes |

1. Web Width (H): 100-900mm |

|

2. Flange Width (B): 100-300mm |

|

|

3. Web Thickness (t1): 5-30mm |

|

|

Length |

9m 12m or Customized |

|

Standard |

JIS EN ASTM ,ect. |

|

Material |

Q235B Q345B Q420C Q460C SS400 SS540 S235 S275 S355 A36 A572 G50 G60 A992 G300 |

|

Technique |

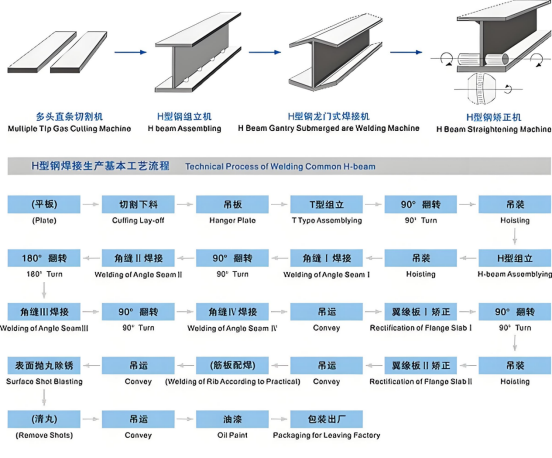

Hot / Cold Rolled/Welding |

|

Application |

Construction structure |

|

Inspection |

SGS BV INTERTEK |

|

Packing |

In bundle fasten by steel strip |

|

Surface |

Polishing, annealing, pickling, bright |

|

Machining |

According to grade 50 for ASTM A572 and ASTM A992 Standard

|

Yield strength, psi |

Tensile strength, psi |

Elongation in 8” |

Elongation in 2” |

|

50,000 |

65,000 |

18 |

21 |

Chemical composition

The beams must have a chemical composition in accordance with ASTM A572 and ASTM A992.

|

Element |

ASTM A572 |

ASTM A992 |

|

C |

0.23 |

0.23 |

|

Mn |

1.35 |

0.50 - 1.60 |

|

P |

0.03 |

0.035 |

|

S |

0.03 |

0.045 |

|

Si, max |

|

0.4 |

|

V, max |

|

0.15 |

|

Nb, max. |

|

0.05 |

|

Cu, max. |

|

0.6 |

|

Ni, max. |

|

0.45 |

|

Cr, max. |

|

0.35 |

|

Mo, max. |

|

0.15 |

Maximum values of V, Nb, Ti and N2 depends on de beam

Superficial quality

Rust: No oxidation or slight oxidation on no more than 50% of the surface. No corrosion

Free of surface lamination defects (no mil defects)

Cut: Straight, without residue (straight cut).

Handling and storage

Loading and unloading

Your email address will not be published. Required fields are marked with *

Their products are of excellent quality and they offer generous discounts. This is their third cooperation