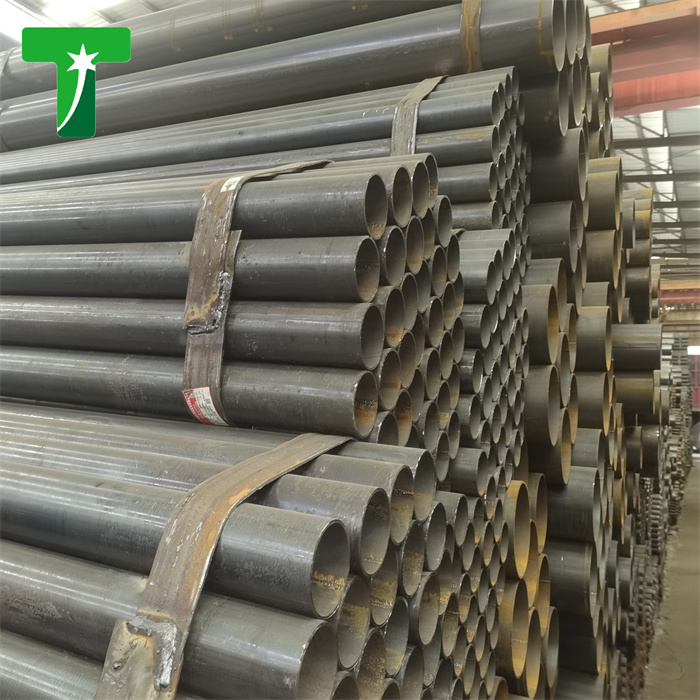

Structural Steel Tubes for Construction ASTM A500 Gr.B/C Certified

- Carbon Steel Grades: API 5L (B, X42-X80), ASTM A53 (A/B), DIN 2448. Perfect for oil/gas transmission, water pipelines, and structural framing—offering superior tensile strength and impact resistance.

- Stainless Steel Grades: ASTM A312 (304, 316, 316L). Resistant to rust, chemicals, and high temperatures, ideal for food processing, pharmaceuticals, and marine engineering.

- Alloy Steel Grades: ASTM A672 (C60-C90). Designed for high-pressure, high-temperature applications like power plants and industrial boilers.

- Outer Diameter (OD): 1/2" (12.7mm) to 63" (1600mm)

- Wall Thickness: SCH 10, SCH 20, SCH 40, SCH 80, SCH 160, XS, XXS (or custom per request)

- Length: 6m, 12m (standard), or cut-to-length (3m-18m) for easy transportation and on-site use.

- End Types: Plain End (PE), Beveled End (BE), Threaded End (TE) to fit different connection requirements.

- Oil & Gas: Transmission pipelines, well casings, and offshore platforms (API 5L X65/X70 grades).

- Water & Wastewater: Municipal water supply, sewage treatment, and irrigation systems (ASTM A53).

- Construction: Structural columns, scaffolding, and building frames (carbon steel grades).

- Manufacturing: Machinery parts, automotive components, and storage tanks (stainless/alloy steel).

- Energy: Power plant pipelines (high-temperature alloy grades for steam and heat transfer).

- Proven Expertise: 18 years of serving global clients—we understand international standards (ASME, BS, JIS) and local market needs.

- Quality Assurance: 100% inspection (hydrostatic, ultrasonic, visual) before shipment; zero-defect record for 5 consecutive years.

- Custom Solutions: From material selection to size customization, we tailor pipes to your project’s unique demands.

- Competitive Pricing: Direct factory supply (no middlemen) + bulk raw material purchasing = cost savings for you.

|

O.D. |

W.T. |

Length(m) |

|||||||

|

Inch |

mm |

Min.Yield Strength(Mpa) |

|||||||

|

Inch |

mm |

245(B) |

290(X42) |

360(X52) |

415(X60) |

450(X65) |

485(X70) |

555(X80) |

|

|

16 |

406 |

6.0-14.0 |

6.0-13.0 |

6.0-12.0 |

6.0-11.0 |

6.0-10.5 |

6.0-10.0 |

6.0-9.0 |

6.0-12.3 |

|

18 |

457 |

6.0-15.0 |

6.0-14.0 |

6.0-13.0 |

6.0-12.0 |

6.0-11.5 |

6.0-11.0 |

6.0-10.0 |

6.0-12.3 |

|

20 |

508 |

6.0-16.0 |

6.0-15.0 |

6.0-14.0 |

6.0-13.0 |

6.0-12.5 |

6.0-12.0 |

6.0-11.0 |

6.0-12.3 |

|

22 |

559 |

6.0-17.0 |

6.0-16.0 |

6.0-15.0 |

6.0-14.0 |

6.0-13.5 |

6.0-13.0 |

6.0-12.0 |

6.0-12.3 |

|

24 |

610 |

6.0-18.0 |

6.0-17.0 |

6.0-16.0 |

6.0-15.0 |

6.0-14.5 |

6.0-14.0 |

6.0-13.0 |

6.0-12.3 |

|

26 |

660 |

6.0-19.0 |

6.0-18.0 |

6.0-17.0 |

6.0-16.0 |

6.0-15.0 |

6.0-15.0 |

6.0-14.0 |

6.0-12.3 |

|

28 |

711 |

6.0-20.0 |

6.0-19.0 |

6.0-18.0 |

6.0-17.0 |

6.0-16.5 |

6.0-16.0 |

6.0-15.0 |

6.0-12.3 |

|

30 |

762 |

7.0-21.0 |

7.0-20.0 |

7.0-19.0 |

7.0-18.0 |

7.0-17.5 |

7.0-17.0 |

7.0-16.0 |

6.0-12.3 |

|

32 |

813 |

7.0-22.0 |

7.0-21.0 |

7.0-20.0 |

7.0-19.0 |

7.0-18.5 |

7.0-18.0 |

7.0-17.0 |

6.0-12.3 |

|

34 |

864 |

7.0-23.0 |

7.0-22.0 |

7.0-21.0 |

7.0-20.0 |

7.0-19.5 |

7.0-19.0 |

7.0-18.0 |

6.0-12.3 |

|

36 |

914 |

8.0-24.0 |

8.0-23.0 |

8.0-22.0 |

8.0-21.0 |

8.0-20.5 |

8.0-20.0 |

8.0-19.0 |

6.0-12.3 |

|

38 |

965 |

8.0-25.0 |

8.0-24.0 |

8.0-23.0 |

8.0-22.0 |

8.0-21.5 |

8.0-21.0 |

8.0-20.0 |

6.0-12.3 |

|

40 |

1016 |

8.0-26.0 |

8.0-25.0 |

8.0-24.0 |

8.0-23.0 |

8.0-22.5 |

8.0-22.0 |

8.0-21.0 |

6.0-12.3 |

|

42 |

1067 |

8.0-26.0 |

8.0-25.0 |

8.0-24.0 |

8.0-23.0 |

8.0-22.5 |

8.0-22.0 |

8.0-21.0 |

6.0-12.3 |

|

44 |

1118 |

9.0-27.0 |

9.0-26.0 |

9.0-24.5 |

9.0-23.5 |

9.0-22.8 |

9.0-22.0 |

9.0-21.0 |

6.0-12.3 |

|

46 |

1168 |

9.0-27.0 |

9.0-26.0 |

9.0-24.0 |

9.0-23.5 |

9.0-22.8 |

9.0-22.0 |

9.0-21.0 |

6.0-12.3 |

|

48 |

1219 |

9.0-28.0 |

9.0-27.0 |

9.0-25.4 |

9.0-24.0 |

9.0-23.5 |

9.0-23.0 |

9.0-22.0 |

6.0-12.3 |

|

52 |

1321 |

9.0-28.0 |

9.0-27.0 |

9.0-25.4 |

9.0-24.2 |

9.0-23.5 |

9.0-23.0 |

9.0-22.0 |

6.0-12.3 |

|

56 |

1422 |

10.0-29.0 |

10.0-28.0 |

10.0-26.0 |

10.0-24.5 |

10.0-23.8 |

10.0-23.0 |

10.0-22.0 |

6.0-12.3 |

|

60 |

1524 |

10.0-29.0 |

10.0-28.0 |

10.0-26.0 |

10.0-24.5 |

10.0-23.8 |

10.0-23.0 |

10.0-22.0 |

6.0-12.3 |

|

64 |

1626 |

10.0-30.0 |

10.0-29.0 |

10.0-27.0 |

10.0-25.4 |

10.0-24.8 |

10.0-24.0 |

10.0-23.0 |

6.0-12.3 |

|

68 |

1727 |

10.0-30.0 |

10.0-29.0 |

10.0-27.0 |

10.0-25.4 |

10.0-24.8 |

10.0-24.0 |

10.0-23.0 |

6.0-12.3 |

|

72 |

1829 |

10.0-30.0 |

10.0-29.0 |

10.0-27.0 |

10.0-25.4 |

10.0-24.8 |

10.0-24.0 |

10.0-23.0 |

6.0-12.3 |

Tolerance of Outside Diameter and Wall Thickness

|

Types |

Standard |

|||||

|

SY/T5040-2000 |

SY/T5037-2000 |

SY/T9711.1-1977 |

ASTM A252 |

AWWA C200-97 |

API 5L PSL1 |

|

|

Tube end OD deviation |

±0.5%D |

±0.5%D |

-0.79mm~+2.38mm |

<±0.1%T |

<±0.1%T |

±1.6mm |

|

Wall thickness |

±10.0%T |

D<508mm, ±12.5%T |

-8%T~+19.5%T |

<-12.5%T |

-8%T~+19.5%T |

5.0mm<t<15.0mm, ±0.11="" <="" p="" style="padding: 0px; margin: 0px;"> |

|

D>508mm, ±10.0%T |

T≥15.0mm, ±1.5mm |

|||||

Chemical Composition and Mechanical Properties

|

Standard |

Grade |

Chemical Composition(max)% |

Mechanical Properties(min) |

|||||

|

C |

Mn |

Si |

S |

P |

Yield Strength(Mpa) |

Tensile Strength(Mpa) |

||

|

GB/T700-2006 |

A |

0.22 |

1.4 |

0.35 |

0.050 |

0.045 |

235 |

370 |

|

B |

0.2 |

1.4 |

0.35 |

0.045 |

0.045 |

235 |

370 |

|

|

C |

0.17 |

1.4 |

0.35 |

0.040 |

0.040 |

235 |

370 |

|

|

D |

0.17 |

1.4 |

0.35 |

0.035 |

0.035 |

235 |

370 |

|

|

GB/T1591-2009 |

A |

0.2 |

1.7 |

0.5 |

0.035 |

0.035 |

345 |

470 |

|

B |

0.2 |

1.7 |

0.5 |

0.030 |

0.030 |

345 |

470 |

|

|

C |

0.2 |

1.7 |

0.5 |

0.030 |

0.030 |

345 |

470 |

|

|

BS En10025 |

S235JR |

0.17 |

1.4 |

- |

0.035 |

0.035 |

235 |

360 |

|

S275JR |

0.21 |

1.5 |

- |

0.035 |

0.035 |

275 |

410 |

|

|

S355JR |

0.24 |

1.6 |

- |

0.035 |

0.035 |

355 |

470 |

|

|

DIN 17100 |

ST37-2 |

0.2 |

- |

- |

0.050 |

0.050 |

225 |

340 |

|

ST44-2 |

0.21 |

- |

- |

0.050 |

0.050 |

265 |

410 |

|

|

ST52-3 |

0.2 |

1.6 |

0.55 |

0.040 |

0.040 |

345 |

490 |

|

|

JIS G3101 |

SS400 |

- |

- |

- |

0.050 |

0.050 |

235 |

400 |

|

SS490 |

- |

- |

- |

0.050 |

0.050 |

275 |

490 |

|

|

API 5L PSL1 |

A |

0.22 |

0.9 |

- |

0.03 |

0.03 |

210 |

335 |

|

B |

0.26 |

1.2 |

- |

0.03 |

0.03 |

245 |

415 |

|

|

X42 |

0.26 |

1.3 |

- |

0.03 |

0.03 |

290 |

415 |

|

|

X46 |

0.26 |

1.4 |

- |

0.03 |

0.03 |

320 |

435 |

|

|

X52 |

0.26 |

1.4 |

- |

0.03 |

0.03 |

360 |

460 |

|

|

X56 |

0.26 |

1.1 |

- |

0.03 |

0.03 |

390 |

490 |

|

|

X60 |

0.26 |

1.4 |

- |

0.03 |

0.03 |

415 |

520 |

|

|

X65 |

0.26 |

1.45 |

- |

0.03 |

0.03 |

450 |

535 |

|

|

X70 |

0.26 |

1.65 |

- |

0.03 |

0.03 |

585 |

570 |

|

Your email address will not be published. Required fields are marked with *

Their products are of excellent quality and they offer generous discounts. This is their third cooperation